DC Motor Controller Guide: Functions, Types, and Selection Tips

DC motors are essential components in countless modern applications, from electric vehicles and robotics to home appliances and industrial automation. But for these motors to operate effectively and safely, a key piece of hardware is required—the DC motor controller.

If you are not familiar with this component, this guide will help you understand what a DC motor controller is, what it does, the different types available, and how to choose the right one for your application.

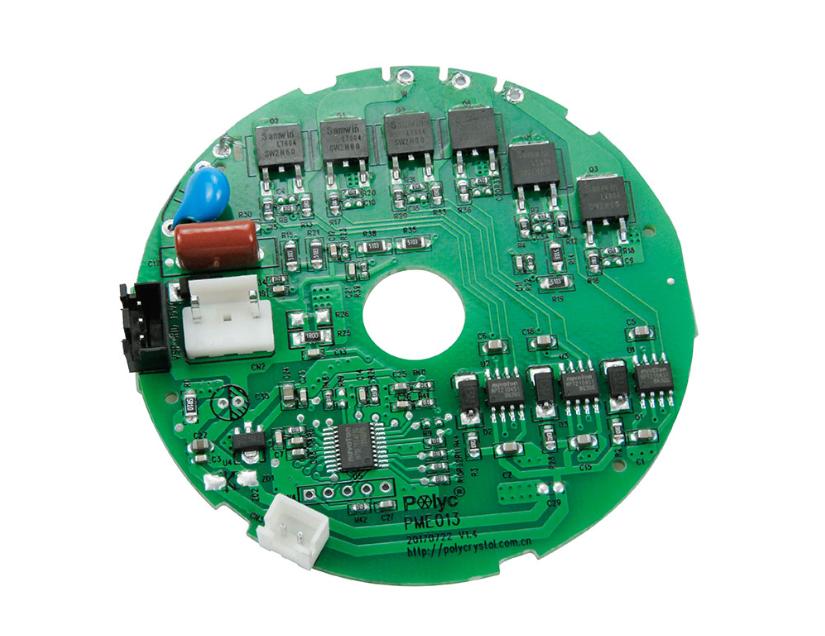

Picture shown: a BLDC motor controller for cordless vacuum cleaner

What is a DC Motor Controller?

A DC motor controller is an electronic device that regulates the operation of a direct current (DC) motor. It acts as the interface between the motor and the power supply, adjusting parameters like voltage and current to control the motor's speed, direction, torque, and more.

The basic principle of operation involves modulating the power delivered to the motor using techniques like pulse width modulation (PWM). By doing so, the controller ensures smooth motor operation while protecting both the motor and the system from electrical faults, overloads, or thermal issues.

Without a motor controller, a DC motor would run uncontrollably when connected to a power source, leading to potential damage and inefficient operation.

Key Functions of DC Motor Controllers

Modern DC motor controllers offer a wide range of functions to optimize motor performance. Some of the most essential features include:

l Speed Control: Adjusts the motor's speed by regulating the voltage or using PWM signals. This is vital in applications where precision is required, such as in conveyor belts or drones.

l Direction Control: Reverses the polarity of the power supply to the motor, allowing it to rotate in the opposite direction. This is essential for automated systems that require bidirectional movement.

l Torque Control: Maintains or limits the torque output by regulating the current supplied to the motor, preventing mechanical wear or overload.

l Braking: Implements dynamic or regenerative braking methods to slow down or stop the motor quickly and safely.

l Protection Features: Includes overcurrent, overvoltage, overtemperature, and short-circuit protection to extend the lifespan of both the motor and controller.

Types of DC Motor Controllers

There are two main types of DC motor controllers:

1. Brushed DC Motor Controllers

These controllers are designed for use with traditional brushed DC motors. They are generally simpler and typically less expensive and can be commonly found in basic applications like toys, small appliances, and low-cost automation systems.

2. Brushless DC (BLDC) Motor Controllers

BLDC motors lack brushes and commutators. Therefore, BLDC motor controllers are inherently more complex, as they must manage the motor's electronic commutation. These controllers use sensors or sensorless algorithms to monitor rotor position and switch phases accordingly. Usually, they can be found in high-performance or noise-sensitive applications.

Picture shown: a BLDC motor controller for high pressure fan

How to Choose the Right DC Motor Controller

When selecting a DC electric motor controller, consider the following factors:

l Motor Specifications: Know your motor's voltage, current, power rating, and type (brushed or brushless). Your controller must be compatible with these specifications.

l Application Requirements: Identify what your system needs—do you require precise speed regulation, torque control, or real-time communication with other systems? Look for features like adjustable speed ranges, feedback support (such as encoders or Hall sensors), and communication protocols.

l Environmental Conditions: Consider whether the controller will operate in extreme temperatures, dusty environments, or areas with vibration or moisture. Ruggedized controllers with protective enclosures may be necessary.

l Budget Constraints: While it's tempting to go for the cheapest option, long-term reliability and efficiency often justify investing in a high-quality controller—especially for critical or high-performance applications.

Why Choose Power Motor?

At Power Motor, we don't just provide motors—we offer complete drive solutions. With over 20 years of experience in motor design and control systems, we supply customized DC motor controllers, including BLDC motor controllers, for industries ranging from home automation to industrial machinery.

Our team of experts works closely with clients to ensure each motor controller is optimized for performance, durability, and ease of integration. Whether you need a simple brushed motor controller or a sophisticated brushless motor controller, we have the capabilities to deliver!

Conclusion

Choosing the right DC motor controller is essential for achieving optimal performance, efficiency, and safety in any motor-driven application. From controlling speed and direction to ensuring system protection, a reliable controller is the heart of any motion application.

At Power Motor, we're committed to delivering top-tier DC motor and controller solutions backed by technical expertise and industry-leading support. Contact us today to find the best DC motor controller for your project!