A Comprehensive Guide About AC Motor Controllers

AC motors are widely used—from industrial plants and HVAC systems to everyday appliances like washing machines and air conditioners. They offer efficiency, reliability, and versatility and deliver optimal performance with a crucial component, the AC motor controllers.

These essential devices regulate speed, torque, and power consumption, making AC motors more efficient and adaptable for different tasks. In this guide, we'll explore what AC motor controllers are, how they work, the different types available, and how to choose the right one for your needs.

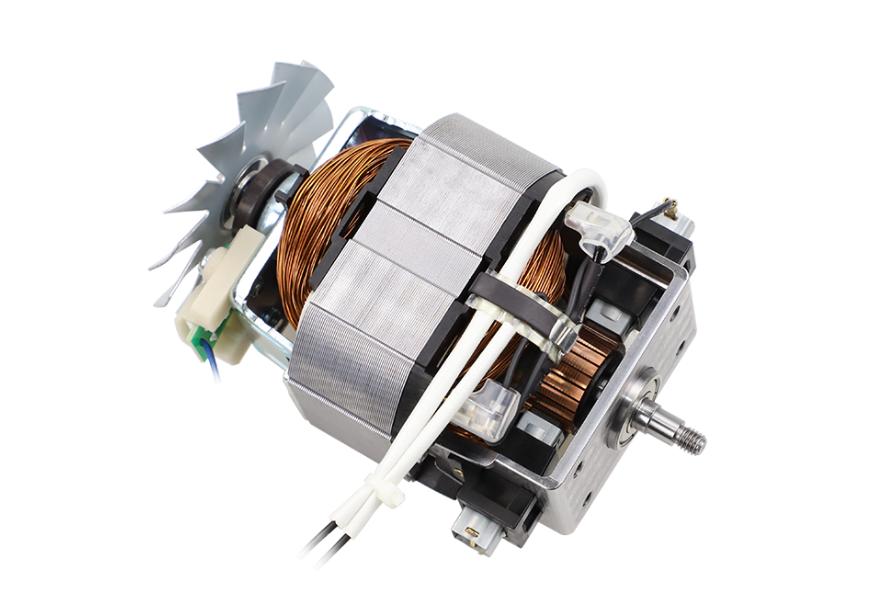

Picture shown: an AC universal motor speed controller

What Are AC Motor Controllers?

An AC motor controller is an electronic device that manages the operation of an AC motor by controlling its speed, torque, and direction. It ensures the motor operates under optimal conditions, helping extend its lifespan and reduce energy consumption.

The basic working principle involves three main components:

l Rectifier: Converts incoming AC power into DC.

l DC Circuit: Conditions the power, often by smoothing or filtering.

l Inverter: Converts the conditioned DC back into a variable frequency AC, which controls the motor's speed and torque.

By delivering specific frequency and voltage to the motor, AC electric motor controllers can precisely regulate its performance.

Types of AC Motor Controllers

There are several types of AC motor controllers tailored to various applications and performance needs. Here are three main types:

l Variable Voltage Inverter (VVI)

Early VVI controllers adjust motor speed by varying the voltage and frequency applied to the motor in a stepped manner. While simple in design, they are generally less efficient and provide less precise control than other types.

l Pulse Width Modulation (PWM)

The PWM motor controller is the most common type used today. It modulates the width of the voltage pulses to control the motor's speed and torque. PWM offers high efficiency, smooth control, and minimal energy loss, making it ideal for many industrial and commercial applications.

l Flux Vector Drives

These controllers provide extremely accurate torque and speed control by calculating the magnetic flux in the motor. They are especially ideal in applications that require rapid changes in speed or torque.

Advantages of Using AC Motor Controllers

Integrating AC electric motor controllers into your systems offers numerous benefits:

l Energy Efficiency

Motor controllers optimize power usage, helping reduce energy costs. By running motors only when needed and at the required speed, they eliminate unnecessary energy waste.

l Extended Motor Lifespan

AC motor controllers can provide soft-start and soft-stop capabilities. This gentle handling reduces wear and tear, extending the service life of both the motor and connected equipment.

l Precise Control

Applications requiring fine adjustments benefit greatly from the highly accurate speed and torque control provided by modern motor controllers, especially PWM motor controllers.

l Enhanced Safety

By controlling acceleration, deceleration, and limiting inrush currents, AC motor controllers help prevent equipment damage and reduce the risk of electrical and mechanical faults. They also support integration with automated safety and monitoring systems.

Applications of AC Motor Controllers

AC motor controllers are versatile and used across multiple industries:

l Industrial Automation

In conveyor belts, pumps, and fans, controllers allow smooth start/stop functions and fine speed adjustments to improve efficiency and reduce downtime.

l HVAC Systems and Compressors

Controllers regulate fan and compressor speeds, maintaining consistent temperatures while using less energy.

l Consumer Appliances

From washing machines to air conditioners, AC motor controllers make appliances smarter and more energy-efficient.

How to Select the Right AC Motor Controller

Choosing the right controller involves evaluating several key factors:

l Motor Type and Size

Ensure the controller is compatible with the motor's voltage, phase, and horsepower requirements.

Picture shown: an AC universal motor for blender or mixer

l Application Requirements

Different tasks require different control precision. For example, a PWM motor controller is ideal for applications needing tight control over speed.

l Environmental Conditions

Consider temperature, humidity, and exposure to dust or chemicals. Controllers rated for harsh environments may be necessary in industrial settings.

l Budget

Cost is always a factor, but it's essential to balance initial investment with long-term energy savings and durability.

Why Choose Power Motor?

At Power Motor, we don't just offer motors—we engineer custom AC motor and controller solutions that fit your exact needs. With over 20 years of experience in motion control, we provide high-performance AC motor controllers that are both reliable and energy-efficient. Whether you need a PWM motor controller for a smart appliance or a robust solution for an industrial machine, we're here to help.

Conclusion

AC motor controllers are essential for maximizing the performance, efficiency, and safety of electric motors across various applications. From industrial machinery to everyday appliances, they offer precise control and significant energy savings.

At Power Motor, we pride ourselves on delivering dependable and innovative motor and controller solutions for different motion control needs. Whether you're upgrading existing systems or starting a new project, you are more than welcome to contact us for expert advice and offerings!