Planetary Gear Motor vs. Spur Gear Motor: Difference Explained

Gear motors are crucial in many industrial and mechanical systems, enabling precise torque and speed control through integrated gear systems. Among the many types, two of the most commonly used are planetary gear motors and spur gear motors.

In this article, Power Motor will compare these two technologies in depth to help engineers, designers, and decision-makers understand their differences and determine which best suits their needs.

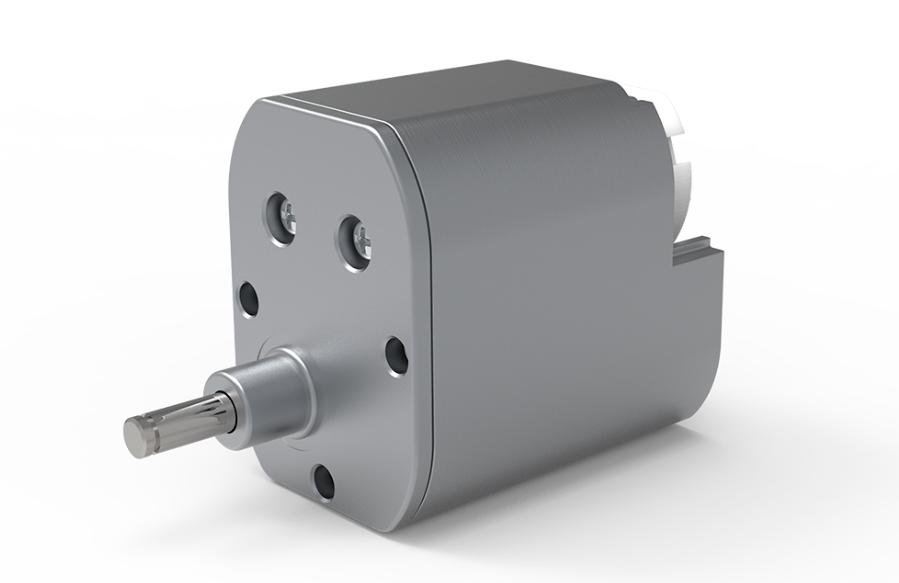

Picture shown: a planetary gear motor for logistics robot

What is a Planetary Gear Motor?

A planetary gear motor—also known as a planetary gearbox motor—is a compact and efficient geared motor system that features three main components: a central sun gear, multiple planet gears (satellites) surrounding it, and a fixed outer ring gear. The planet gears (satellites) rotate around the sun gear while also meshing with the ring gear, distributing the load across multiple contact points.

1. Advantages of Planetary Gear Motors:

l High Transmission Efficiency: Planetary gear motors efficiently transfer input power to output, often achieving higher transmission efficiencies than general motors.

l Compact and Space-Saving Design: Their coaxial arrangement and load distribution allow for high torque output in a smaller footprint, reducing equipment size and weight.

l High Torque Density: Multiple planet gears share the load, enabling greater torque capacity within the same volume, making them suitable for applications requiring strong torque at low speeds.

l High Precision and Stability: Even power distribution among gears results in reduced backlash, high rotational accuracy, low vibration, and noise, which is critical in robotics and precision machinery.

2. Limitations of Planetary Gear Motors:

l Complexity and Cost: The design and manufacturing complexity of planetary gear motors can lead to higher initial costs compared to simpler gear systems.

l Potential for Increased Heat: High torque and compact design may lead to heat buildup, requiring careful thermal management in some applications.

3. Common Applications of Planetary Gear Motors:

Due to high torque, compact size, and excellent efficiency, planetary gear motors are widely used in robotics, industrial automation, medical devices, automotive systems, and consumer electronics, providing precise, reliable, and quiet operation for various demanding applications.

What is a Spur Gear Motor?

A spur gear motor features a gearbox that contains several spur gears with straight teeth mounted on parallel shafts. The gears mesh together, typically with a small pinion gear on the motor shaft driving a larger gear on the output shaft, achieving speed reduction and torque increase based on the gear teeth ratio. It's one of the most basic and cost-effective gear systems available.

Picture shown: a spur gear motor for vending machine

1. Advantages of Spur Gear Motors:

l Simple and Cost-Effective Design: Spur gear motors have a straightforward structure with straight teeth on parallel shafts, making them easy and inexpensive to manufacture and integrate into mechanical systems.

l High Efficiency: Due to the straight teeth and direct engagement, spur gears have high power transmission efficiency with minimal energy loss, especially at moderate speeds and loads.

l Reliable and Consistent Speed: Spur gears maintain a constant angular velocity ratio, ensuring stable and dependable motion transfer with minimal slippage.

l No Axial Thrust: The straight teeth produce forces only in the radial direction, so there is no axial thrust on the shafts, simplifying bearing requirements.

l Ease of Maintenance: Their simple construction allows for easy maintenance and replacement of parts.

2. Limitations of Spur Gear Motors:

l Noise and Vibration: The abrupt engagement of straight teeth can cause high noise and vibration, especially at high speeds or under heavy loads.

l Limited Torque Capacity: Spur gear motors are less effective at transmitting very high torque compared to other gear types like planetary or helical gears.

l Sensitivity to Misalignment: Spur gears require precise alignment; misalignment can cause increased wear, reduced efficiency, and more noise.

3. Applications of Spur Gear Motors:

Spur gear motors are commonly used in applications requiring simple, efficient, and cost-effective power transmission. Typical uses include conveyor systems, printers, packaging machines, and basic automation equipment, where moderate torque, consistent speed, and low complexity are essential for reliable operation.

Comparison Table: Planetary vs. Spur Gear Motors

Feature | Planetary Gear Motor | Spur Gear Motor |

Structure | Sun gear, planet gears, and ring gear | Gears with straight teeth on parallel shafts |

Torque Capacity | High torque in compact size | Moderate torque, typically larger size for the same output |

Noise Level | Typically lower | Higher noise, especially at high speeds |

Maintenance | More complex, higher precision | Simple, easy to maintain |

Cost | Higher due to complex structure | Cost-effective |

Best for | Robotics, industrial automation, medical devices, and systems needing low backlash and balanced load distribution. | Conveyor systems, small appliances, pumps, and general machinery where parallel shaft transmission and ease of maintenance are priorities. |

Planetary or Spur Gear Motors: When to Use Which?

When deciding between a planetary gear motor and a spur gear motor, consider the requirements of your specific application:

l Use planetary gear motors when compact design, high torque, and efficiency are priorities. They're best suited for applications requiring precision, such as robotic arms, CNC machines, or medical equipment.

l Use spur gear motors when the budget is tight and the application doesn't demand high torque or precision. They are ideal for simple mechanical systems and consumer appliances.

Each motor type has its ideal use case, and choosing the right one can lead to improved system performance and longer operational life.

Power Motor: Your Trusted Gear Motor Partner

At Power Motor, we specialize in designing and manufacturing both planetary gearbox motors and spur gear motors. With decades of experience in motor engineering, our team provides tailored solutions for various industries, from medical and home appliances to industrial automation and electric mobility.

We pride ourselves on delivering gear motors with optimal performance, reliability, and customization options. Whether you require high torque in a compact form or a cost-effective solution for light-duty use, we can guide you to the best motor configuration.

Our in-house R&D capabilities ensure we stay ahead of the curve, continuously innovating to meet evolving client demands.

Conclusion

In summary, the key differences between planetary gear motors and spur gear motors lie in their design, torque capabilities, and ideal use cases. Planetary motors offer high performance and compactness, making them perfect for demanding applications, while spur motors provide a simpler and more economical option for everyday uses.

At Power Motor, we're here to help you make the best gear motor choice for your needs. Whether you're developing a new product or upgrading an existing system, contact us today for expert advice and customized motor solutions!