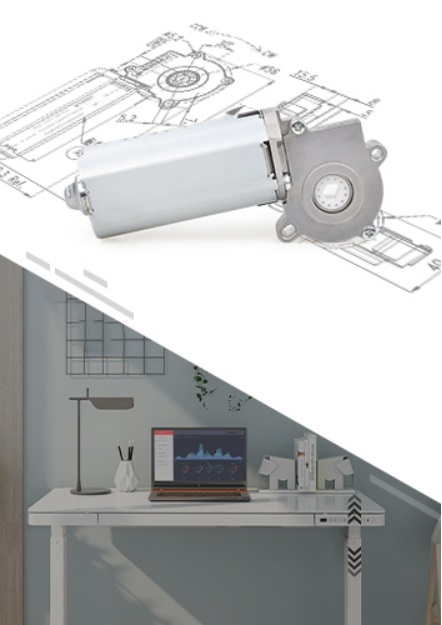

Worm Gear Manufacturer Secrets Maximizing the Sliding Action for Self-Locking Capability

The worm gear set is unique in the world of mechanical power transmission because its operation is dominated not by the smooth, efficient rolling contact found in spur or helical gears, but by sliding contact. This critical difference in kinematics is precisely what gives the worm gear its defining characteristics: high torque reduction and, most importantly, its inherent self-locking capability. As a specialized worm gear manufacturer, Power Motor engineers the system to maximize this sliding friction for reliable performance.

The Physics of Sliding Contact

In a worm gear set, the worm (the screw) drives the worm wheel (the larger gear). The motion of the worm's thread across the teeth of the worm wheel is a predominantly sliding motion, rather than rolling. The lead angle of the worm is shallow, meaning that as the worm turns, it essentially pushes the worm wheel teeth along a long, low-angle ramp. This high degree of sliding generates substantial frictional force. It is this controlled friction that dictates the efficiency and the self-locking function of the assembly. A skilled worm gear manufacturer carefully selects materials—often using a hard metal for the worm and a softer bronze alloy for the worm wheel—to minimize wear while capitalizing on the necessary sliding friction.

Maximizing the Self-Locking Feature

The ability of a worm gear system to be self-locking—meaning the worm wheel cannot turn the worm—is entirely dependent on this sliding friction exceeding the tangential force applied by the worm wheel. This provides a crucial safety lock, eliminating the need for an external brake in applications like lifts or heavy positioning systems. The degree of self-locking is determined by the lead angle of the worm; a smaller, shallower lead angle results in a higher degree of sliding friction and a more reliable lock. As leading worm wheel gear supplier, Power Motor designs high-ratio worm sets specifically with shallow lead angles to maximize the sliding interaction and guarantee non-reversibility.

The Role of the Worm Wheel Gear Supplier

The performance and longevity of a worm gear set are highly sensitive to manufacturing precision. The geometry and material pairing of the worm and the gear are vital to managing the sliding contact. As a trusted worm gear manufacturer, we ensure the tooth profiles are manufactured to tight tolerances to promote even contact and reduce localized wear. Furthermore, the worm wheel material—often a specific grade of bronze—must be chosen by a reliable worm wheel gear supplier to withstand the continuous sliding action. By controlling the entire manufacturing process, Power Motor delivers robust, high-performance systems where the sliding motion is engineered for optimum torque holding and long operational life.