The Locking Principle Power Motor Explains the Unidirectional Nature of Worm Gears

Worm gear sets are a unique component in mechanical motion, prized for their ability to deliver massive torque reduction in a compact space. However, their defining and most critical feature is the locking principle, or non-reversibility. In most high-ratio applications, the worm gear (the larger driven wheel) cannot drive the worm (the screw-like driving element). This unidirectional nature provides a powerful safety and functional advantage that is crucial for applications requiring load holding. As a specialized worm gear manufacturer, Power Motor leverages this principle to design incredibly reliable holding systems.

Understanding the Unidirectional Advantage

The mechanical inability of the gear to drive the worm is known as being self-locking or non-reversible. This phenomenon occurs due to the shallow lead angle of the worm thread and the high friction generated between the sliding surfaces of the worm and the gear teeth. When the gear tries to turn the worm, the friction between the surfaces exceeds the tangential force that the gear can apply to the worm. Essentially, the system locks up. This is a deliberate and vital feature utilized in lifting equipment, conveyor belts, and precise positioning systems where the load must be held securely in place when the DC worm gear motor is de-energized.

Designing for Security with a DC Worm Gear Motor

The self-locking property eliminates the need for external braking mechanisms, dramatically simplifying the system design and improving reliability. For instance, in applications like hospital beds or scissor lifts, the safety of the user depends on the load remaining fixed. By integrating a high-quality gear set from a trusted worm gear manufacturer with a robust DC motor, the resulting DC worm gear motor assembly provides inherent safety. This non-reversibility ensures that the system will not back-drive or drift, even under heavy load.

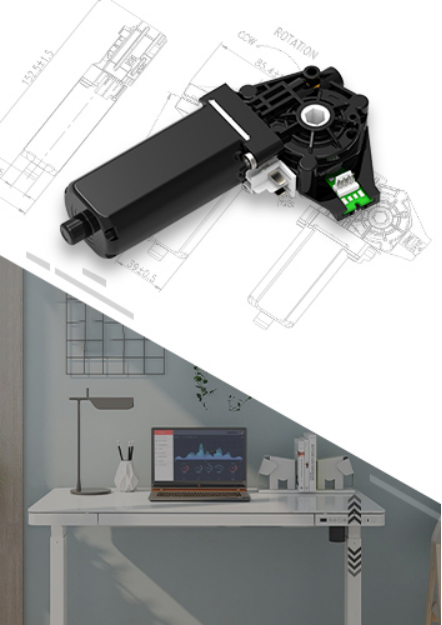

Power Motor’s Expertise as a Worm Gear Manufacturer

Not all worm gear sets are truly self-locking. The non-reversible property is highly dependent on the lead angle and the coefficient of friction, which in turn relies on the quality of the materials, surface finish, and lubrication. A poor quality system may be reversible, defeating the entire purpose. Power Motor guarantees the integrity of this locking principle. As a premier worm gear manufacturer, we precisely control the geometry and materials of our gear sets to ensure reliable non-reversibility in high-ratio applications. Our integrated DC worm gear motor solutions provide the power and the passive safety lock necessary for critical holding applications, giving our customers confidence in their motion control systems.