Is Your Power Seat Stuck Learn the Essential Motor Reset Procedure

A malfunctioning power seat—whether stuck forward, backward, or refusing to tilt—is not just an inconvenience; it's a safety and comfort issue. When the memory is lost or the mechanism jams, the problem often lies not with a broken part, but with the electronic calibration of the car seat motor and its associated control module. Before resorting to expensive replacements, learning the essential motor reset procedure can often restore full functionality. This requires a basic understanding of how the precise mechanical components, like those supplied by a specialized worm gear manufacturer, interact with the motor's position sensor.

Decoding the Car Seat Motor Failure

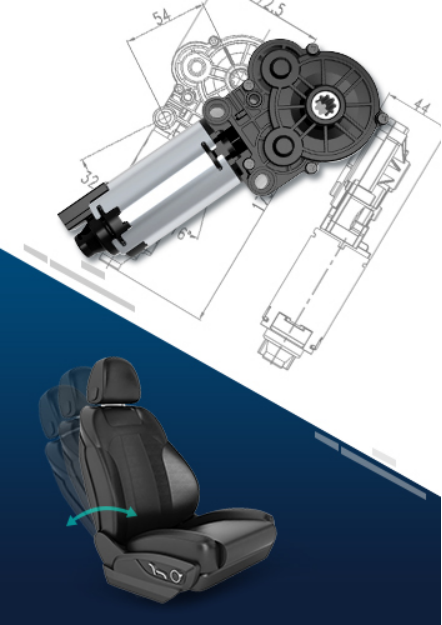

Modern power seats are complex electro-mechanical systems. Each axis of movement (fore/aft, height, and recline) is typically driven by its own small car seat motor connected to the seat mechanism via a gear reduction system. The reliability of this gear system is critical; components from a dedicated worm gear manufacturer ensure the necessary non-back-drivable lock-in position. A common failure mode is the motor losing its 'home' position relative to the physical limits of the track, often due to a low battery, a fuse replacement, or an electrical spike. The control module, which manages the car seat motor and seat memory, becomes confused about where the seat is, causing it to halt.

The Essential Motor Reset Procedure

The goal of the reset procedure is to force the car seat motor and the control module to 'relearn' the physical limits of the seat track, effectively recalibrating the system. While steps vary slightly by vehicle manufacturer, the general process involves a sequence of actions. Start by turning the ignition key to the accessory (ACC) or ON position without starting the engine. Next, attempt to run the stuck axis of the seat all the way to its absolute physical limit in one direction (e.g., fully forward). The motor may groan or move intermittently, but keep the button pressed for several seconds after the seat stops. This crucial step clears any stored fault position. Immediately afterward, run the seat all the way to the opposite physical limit (e.g., fully backward). Again, hold the switch down for several seconds (typically three to five seconds) after the seat stops moving. This action tells the control module that the motor has hit the new physical zero point. Finally, release the switch, and the system should now be recalibrated. Test the seat's full range of motion to verify.

If this manual cycling does not work, the issue may be mechanical—perhaps a jammed cable or damaged gear, requiring a precise replacement part from a worm gear manufacturer.

Power Motor’s Role in Seat System Reliability

As a manufacturer of the precise components that drive these systems, Power Motorunderstands the necessity of reliability and accuracy. Our motors and related gear assemblies are engineered to withstand the demanding, high-torque environment of automotive seating. Whether you are dealing with a simple car seat motor issue or require a full component replacement, understanding the interaction between the motor and the gearing—often a critical part supplied by a worm gear manufacturer—is key to effective troubleshooting. For issues that persist beyond a simple reset, professional diagnosis is recommended to ensure both safety and function.