Beyond the Basics Decoding the Core Physics of Stepper Motor Operation

Stepper motors are the backbone of digital motion control, translating precise electrical pulses into discrete, repeatable mechanical movements. Unlike traditional DC motors, which rotate continuously, a stepper motor moves in fixed angular increments, making them ideal for positioning, indexing, and feed applications found in printers, scanners, and CNC equipment. Understanding the core physics behind this precision is essential for system designers. As a premier stepper motor supplier, Power Motor leverages this deep knowledge to engineer motors that offer unmatched accuracy and torque stability.

The Anatomy of Digital Motion

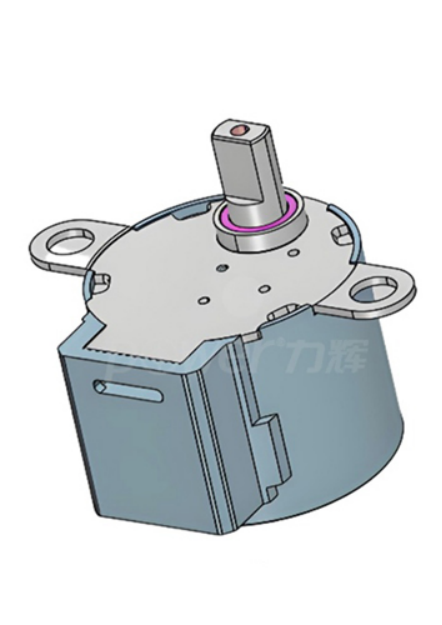

A stepper motor achieves its discrete movement through the precise interaction of electromagnetic poles. It consists of two main parts: the stationary stator, which has multiple wound teeth that act as electromagnets, and the rotating rotor, which is a permanent magnet or soft iron core with precisely cut teeth. The rotor's movement is controlled entirely by digitally switching the current sequence, or phasing, in the stator windings. By energizing a coil, a magnetic field is generated, attracting the rotor teeth and aligning them with the excited stator teeth. The next phase is energized, slightly shifting the magnetic alignment and forcing the rotor to "step" to the new position. This fundamental process is why selecting an experienced stepper motor supplier is crucial—the physical design dictates the precision.

The Role of Full Stepping, Half Stepping, and Microstepping

The complexity of a stepper motor's operation is dictated by the drive electronics. Full stepping involves switching the full current between phases sequentially, yielding the motor’s native step angle (e.g., 1.8°). Half stepping involves alternating between one and two phases being energized, effectively halving the step angle and smoothing motion. The most sophisticated technique is Microstepping, where the current in the windings is controlled sinusoidally to create thousands of fractional steps between the full steps. This dramatically improves resolution and reduces vibration. Power Motor, as an expert stepper motor manufacturer, designs motors with optimized winding impedance and low detent torque, ensuring that these advanced microstepping signals translate into smooth, accurate mechanical output—a necessity for high-end applications like medical diagnostics.

Power Motor’s Commitment to Precision Engineering

The true performance of a stepper motor—its repeatability, holding torque, and speed capability—is a direct function of the quality of its manufacturing and design tolerances. Inferior motors struggle with core losses and have high positional error. As a trusted stepper motor manufacturer, Power Motor controls every detail: from the precise cutting of the stator laminations to the material purity of the permanent magnets. This dedication allows us to minimize static and dynamic error, ensuring that our clients receive a highly reliable product. Whether you need a simple two-phase design or a complex hybrid solution, partnering with Power Motor as your dedicated stepper motor supplier guarantees a motor engineered for maximum positioning accuracy.