How to Control the Speed of a DC Motor

DC motors are the backbone of modern robotics, fans, and industrial automation. However, achieving peak performance requires precision. Understanding how to control the speed of a DC motor is essential for optimizing efficiency and safety. By utilizing various electrical adjustment methods, engineers can tailor motor behavior to meet specific operational demands while preventing system damage and unnecessary energy consumption.

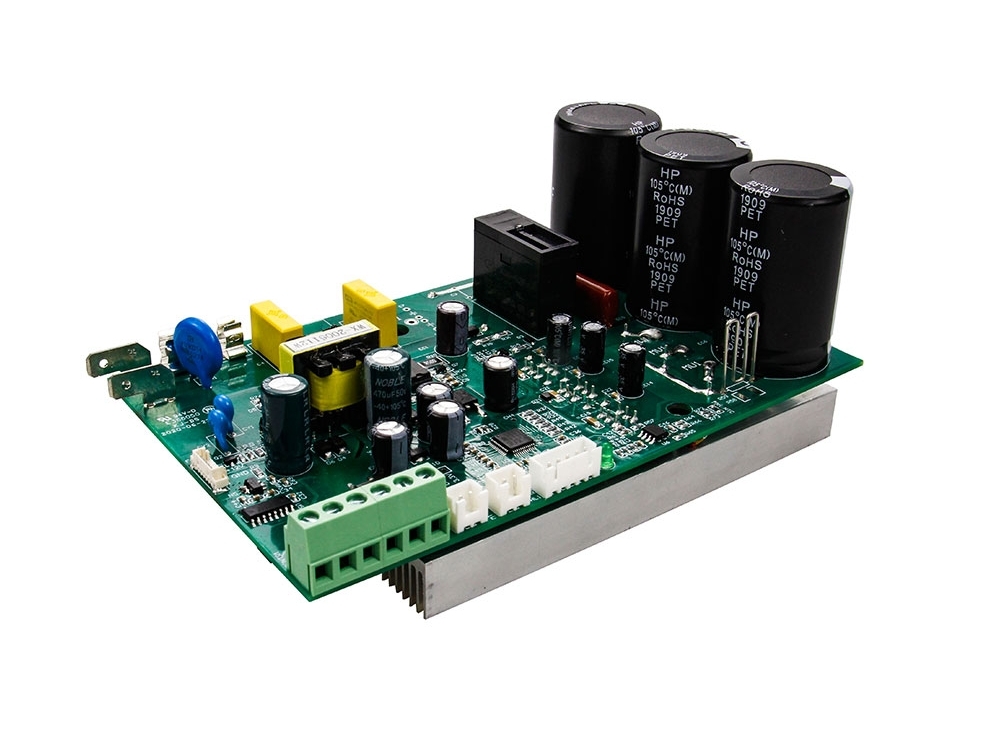

Product shown: 3 phase BLDC motor controller with speed control (rotating speed up to 20,000 rpm)

The Science: How DC Motor Speed Works

Before implementing a control strategy, one must understand the underlying physics governing motor rotation. The relationship between the electrical input and mechanical output of a DC motor could be defined by a fundamental mathematical relationship.

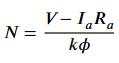

The speed of a DC motor can be expressed by the following formula:

In this equation:

l N represents the speed of rotation.

l V is the applied terminal voltage.

l Ia is the armature current.

l Ra is the internal armature resistance.

l k is the motor construction constant (related to winding turns, pole pairs, etc.).

l Φ is the magnetic flux per pole.

This formula highlights that the speed of the motor is directly proportional to the back electromotive force (Eb = V - Ia Ra) and inversely proportional to the magnetic flux (Φ). Consequently, engineers can manipulate the velocity of a motor by varying the applied voltage, the resistance within the armature circuit, or the strength of the magnetic field.

How to Control the Speed of a DC Motor: 3 Effective Methods

Choosing the right method depends on the specific requirements of the application, such as the need for high efficiency, constant torque, or operation above the rated base speed. Here are the three primary techniques used to create a variable-speed DC electric motor system.

1. Armature Voltage Control (Pulse Width Modulation - PWM)

This is the most prevalent method in modern electronics. It involves adjusting the terminal voltage (V) while keeping the magnetic flux constant. While linear voltage regulation is possible, most high-performance systems utilize pulse width modulation (PWM) for its unique advantages.

l Working Principle: Instead of providing a continuous lower voltage, a PWM controller rapidly switches the power supply "ON" and "OFF." The "duty cycle"—the ratio of the time the signal is high versus the total period—determines the average voltage delivered to the motor.

l Advantages & Applications: PWM offers exceptional efficiency because the switching transistors (MOSFETs) are either fully on or fully off, minimizing power loss as heat. It provides smooth operation and fast response times, making it the gold standard for robotics, precision automation, and consumer electronics where energy conservation is paramount.

2. Flux Control (Field Control)

Flux control involves adjusting the magnetic field current to vary the flux (Φ) within the motor.

l Working Principle: Based on the formula N ∝ 1/Φ, decreasing the flux results in an increase in motor speed. This is often referred to as "field weakening." By reducing the current flowing through the field windings, the magnetic field strength drops, allowing the motor to spin faster.

l Advantages & Drawbacks: This method is uniquely capable of pushing a motor beyond its rated base speed. However, it operates in a "constant power" mode, meaning that as speed increases, the available torque decreases. If the flux is reduced too aggressively, the motor may become unstable.

l Ideal Applications: It is frequently used in electric traction systems, such as trains, and industrial applications where high-speed operation is required without the need for maximum torque at those velocities.

3. Series Resistance (Armature Resistance Control)

This is a more traditional method where a variable resistor, or rheostat, is placed in series with the armature winding.

l Working Principle: By increasing the total resistance (Ra), a larger portion of the supply voltage is dropped across the resistor rather than the armature. This reduces the effective voltage available for rotation, thereby slowing the motor.

l Drawbacks: This method is largely considered inefficient for modern high-performance applications. The energy diverted from the motor is dissipated as wasted heat in the resistor. Furthermore, it results in poor speed regulation; the speed will drop significantly if the load on the motor increases.

l Ideal Applications: You may see this method used in some intermittent, low-cost applications where speed needs to be reduced only for short bursts, such as in certain types of cranes, hoists, or traditional printing presses.

Power Motor’s Solutions for DC Motor Speed Control

For manufacturers requiring reliable and compact solutions, choosing the right drive electronics is as important as the motor itself. Power Motor offers a specialized range of motor controllers designed for brushless DC (BLDC), brushed DC, AC universal, automotive motors, and other motor types. We can partner closely with OEMs to achieve custom functionality, especially for high-demand 12-volt DC motor speed control applications.

Our unique advantages include:

l Advanced BLDC Control Expertise: Power Motor offers diverse control solutions featuring both sensored (Hall, photoelectric, magnetic) and sensorless (Back-EMF, FOC) configurations. We have mastered square wave, sine wave, and field-oriented control (FOC/Vector) technologies to meet diverse operational needs.

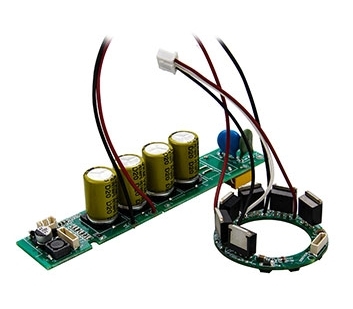

l Ultra-High Speed & Precision: Our controllers support ultra-high-speed FOC (up to 200,000 rpm) and high-precision closed-loop speed regulation (5/100,000). These capabilities are essential for miniaturized, high-performance applications like hair dryers, laser scanners, and medical centrifuges.

l High-Torque & Direct Drive Capability: Utilizing large current handling technology, we provide perfect solutions for direct-drive applications and high-torque tools, ensuring silent operation through optimized FOC control.

l Unique EMC & Integration Solutions: We possess deep industry knowledge of EMC (Electromagnetic Compatibility) challenges, offering proprietary solutions that ensure your products meet strict regulatory standards while maintaining performance.

Product shown: brushless DC motor controller (with speed control) for 100,000 rpm mini hair dryer

Considerations Beyond Speed: Choosing the Right Motor

While speed control is vital, a high-performance system requires a holistic approach to motor selection. When partnering with an OEM/ODM provider like Power Motor, consider these critical factors:

l Torque: Ensure the motor provides sufficient starting torque to move the load from a standstill and enough running torque to maintain speed under load.

l Efficiency: Especially for battery-powered medical devices or portable tools, high efficiency reduces thermal output and extends battery life.

l Thermal Management: Compact designs require sophisticated cooling. Depending on your duty cycle, you may need fan-cooled or totally enclosed non-vented (TENV) configurations.

l IP Ratings: For outdoor automotive components or industrial automation, ingress protection (IP) ratings ensure the motor remains functional against dust and moisture.

l Noise: In medical and smart home applications, minimizing acoustic noise through precision gear design and balanced rotors is essential.

Conclusion

Controlling the speed of a DC motor—whether through PWM, flux control, or resistance—is the key to unlocking the full potential of your equipment. For equipment manufacturers seeking high-performance, customizable, and compact motor solutions, Power Motor stands as an industry leader with over 20 years of expertise.

From initial design to mass production, Power Motor provides the technical excellence required for today’s smart and automated world. Contact Power Motor today to find the perfect motor and controller for your next project!