Amorphous Material Motor Solution

I. The basic situation of the amorphous materials

Amorphous materials are a class of solid materials in which atoms are arranged in a long-range disordered and short-range ordered manner, also known as glassy materials. Unlike traditional crystalline materials, amorphous materials do not have a regular lattice structure, and the atomic arrangement is closer to the random distribution of liquid. This unique structure endows it with a variety of excellent properties: high magnetic permeability, low coercive force, low iron loss and high resistivity. In the field of transformers, amorphous materials have been fully commercialized and applied on a large scale, and it is a very mature and mainstream technology. However, in the field of motors, amorphous materials are still in a critical breakthrough period from the laboratory to the large-scale market and represent a cutting-edge and hot technology.

II. The Market demand

In the field of motors, currently, the mainstream products on the market that can be mass-produced are still mainly silicon steel sheet motors. Silicon steel sheet motors can cover the vast majority of fields, and their production and manufacturing technology as well as cost control are relatively mature. However, in some scenarios where efficiency takes priority, high frequency and high speed are required, temperature rise is limited, and performance is demanded to the extreme, silicon steel sheet motors often have certain limitations. However, amorphous material motors, due to the structural characteristics and performance advantages of their materials, are more suitable for meeting the demands of such scenarios.

III. The solution of Shenzhen Power Motor Industrial Co.,Ltd.

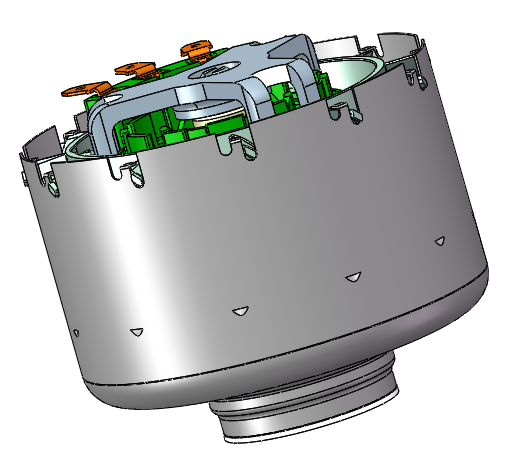

In the design of high-frequency, high-speed, high-efficiency and low-temperature rise vacuum cleaner motors, Shenzhen Power Motor Industrial Co.,Ltd., in addition to using traditional silicon steel sheet motors, has also proposed an amorphous material motor solution. This motor solution uses amorphous materials and manufactures the motor armature chip through laser cutting technology. Under the same production process, with the same drive control ,the amorphous material motors can reach over 40,000 RPM, and the overall efficiency of the vacuum cleaner motor can reach 54%. Compared with the traditional silicon steel sheet motor, the performance of this amorphous material motor has been further improved.

IV. The future plans of Shenzhen Power Motor Industrial Co.,Ltd.

We will continue to research the application of amorphous material motors in other scenarios in the next step, constantly optimize and develop products, and provide customers with more high-quality product customization services. Although cost control and production manufacturing of amorphous material motors are currently rather difficult, it is believed that with the continuous maturation and optimization of material processes, amorphous material motors and traditional silicon steel sheet motors will achieve complementary application fields and long-term coexistence.

Contact Us Today:

Note: This article is contributed by Power Motor Research and Development Department