How Does a 24V DC Electric Motor Work? Working Principle and Applications

A 24V DC electric motor converts electrical energy into mechanical power, offering the necessary torque and speed control under a 24V threshold. These critical components drive innovation in sectors ranging from medical devices to industrial robotics.

In this article, Power Motor will explore them comprehensively, providing you with the technical insights needed to optimize your equipment's performance and efficiency.

Picture shown: 24V Low Noise Bladeless Fan BLDC Motor

Basic Structure and Components of a 24V DC Motor

To understand the performance capabilities of these units, one must look at the synergy between their internal components. While the specific architecture can vary between types, a typical 24V DC motor consists of several key parts:

l Stator: The stationary outer part of the motor. It contains either permanent magnets or electromagnetic windings that create a constant magnetic field.

l Rotor (Armature): The central rotating part made of iron cores wrapped in copper wire. When energized, it generates its own electromagnetic field.

l Commutator: A segmented copper ring attached to the shaft. It acts as a mechanical switch, reversing the current direction in the rotor coils to maintain continuous rotation.

l Brushes: Usually made of carbon or graphite, these components maintain physical contact with the rotating commutator to deliver electricity from the 24V power source to the rotor.

l Shaft: The output component that transfers the generated mechanical energy to external loads like gears, pulleys, or fans.

l Housing: The frame or shell that protects internal components from dust, moisture, and mechanical impact while providing structural support.

It is important to note that while the structure above describes a brushed model, a 24V brushless DC motor (BLDC) eliminates the brushes and commutator. Instead, it utilizes a permanent magnet rotor and an electronic controller to switch the current, which significantly reduces friction and extends the motor's operational life.

How Does a 24V DC Electric Motor Work?

The operation of a 24V DC electric motor is based on the principle of electromagnetism—specifically, the Lorentz force. When a current-carrying conductor is placed within a magnetic field, it experiences a physical force.

The Step-by-Step Operation Process:

1. Power Activation: Once the 24V DC power supply is connected, current flows through the brushes and into the commutator.

2. Magnetic Interaction: As the current flows through the rotor's copper windings, it creates a magnetic field. This field interacts with the stator's fixed magnetic field.

3. Torque Generation: Based on the "like poles repel, opposite poles attract" rule, the interaction between the two magnetic fields generates a torque on the rotor, causing the rotor (and its shaft) to rotate.

4. Commutation: To keep the motor spinning in one direction, the commutator rotates with the shaft and automatically switches the current direction every half-turn, ensuring the repulsion and attraction forces are always aligned to drive rotation.

FAQs About 24V Electric Motors

1. Should you choose a 24V brushed DC motor or a 24V brushless DC motor?

The choice depends on your application's lifespan and maintenance requirements. A brushed motor is cost-effective and simple to control but has a limited lifespan (typically 1,000–5,000 hours) due to brush wear.

Conversely, a 24V brushless DC motor (BLDC) offers higher efficiency (85-90%), quieter operation, and an exceptional lifespan of up to 50,000 hours, though it requires a more complex electronic controller.

2. Should you choose a 24V or a 12V DC motor?

Generally, 24V systems are often superior for efficiency. For the same power output, a 24V motor requires only half the current of a 12V motor. Based on the power loss formula P=I2 x R, lower current results in significantly less heat generation and energy waste.

This allows for thinner, less expensive wiring and better performance over longer distances. For a deeper dive into these technical differences, you can read more about 12V vs. 24V motor comparisons.

Common Applications of 24V DC Electric Motors

Due to their reliability, 24V motors are integrated into diverse high-stakes environments:

1. Industrial and Automation: They power conveyor belts, robotic arms, and automated sorting machines where consistent torque and 24/7 reliability are non-negotiable.

2. Automotive and Mobility: Beyond passenger cars, 24V systems are standard in heavy-duty transit, powering electric bus cooling pumps and mobility aids like high-torque electric wheelchairs.

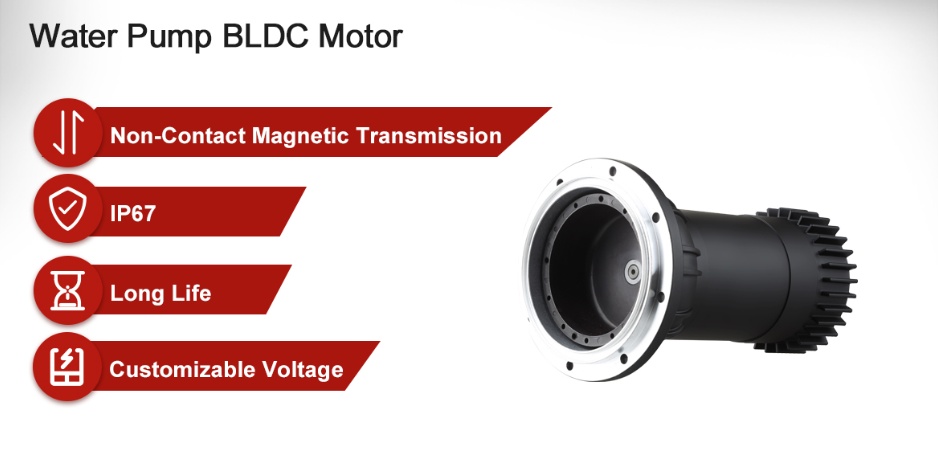

Picture shown: 24V Electric Bus Cooling Water Pump Motor

3. Renewable Energy: 24V motors are used in solar tracking systems to precisely tilt panels toward the sun, as well as in small-scale off-grid wind turbines.

4. Consumer and Commercial Equipment: From high-end smart home automation like motorized blinds to professional-grade medical equipment like MRI pumps and ventilators.

Precision Engineering with Power Motor

As a leading global manufacturer, we at Power Motor specialize in custom motion solutions tailored to specific industrial needs. Our 24V lineup is engineered for high durability, optimized power density, and superior reliability. Key products in our portfolio include:

l 24V Low Noise Bladeless Fan BLDC Motor: Designed by our engineering team for whisper-quiet environments, utilizing advanced BLDC technology for high airflow.

l 24V Drone Motor: A frameless torque motor developed for lightweight, high-performance aerial applications.

l 24V Electric Bus Cooling Water Pump Motor: A robust BLDC solution built by us to withstand the rigorous thermal demands of transit cooling.

l 24V Outer Rotor Fascia Gun Motor: An innovative, compact design offering high torque for professional therapeutic devices.

Conclusion

A 24V DC electric motor delivers an excellent balance of efficiency, torque, and reliability across industrial, commercial, and advanced automation applications. Understanding its working principle helps you make better design and sourcing decisions.

By selecting Power Motor as your partner, you gain access to high-precision, custom-engineered 24V solutions that enhance product longevity. Contact us today to learn how our technology can drive your next project forward!