What Makes Quiet Electric Motors in Cars?

In the era of electric vehicles, cabin silence is the ultimate luxury. Without an engine to mask noise, every auxiliary component must perform flawlessly. For OEMs, specifying a quiet electric motor for applications like power seats and liftgates is critical.

As an experienced manufacturer of quiet electric motors, Power Motor will explore the engineering technologies—from brushless design to precision gears—that deliver this silent performance.

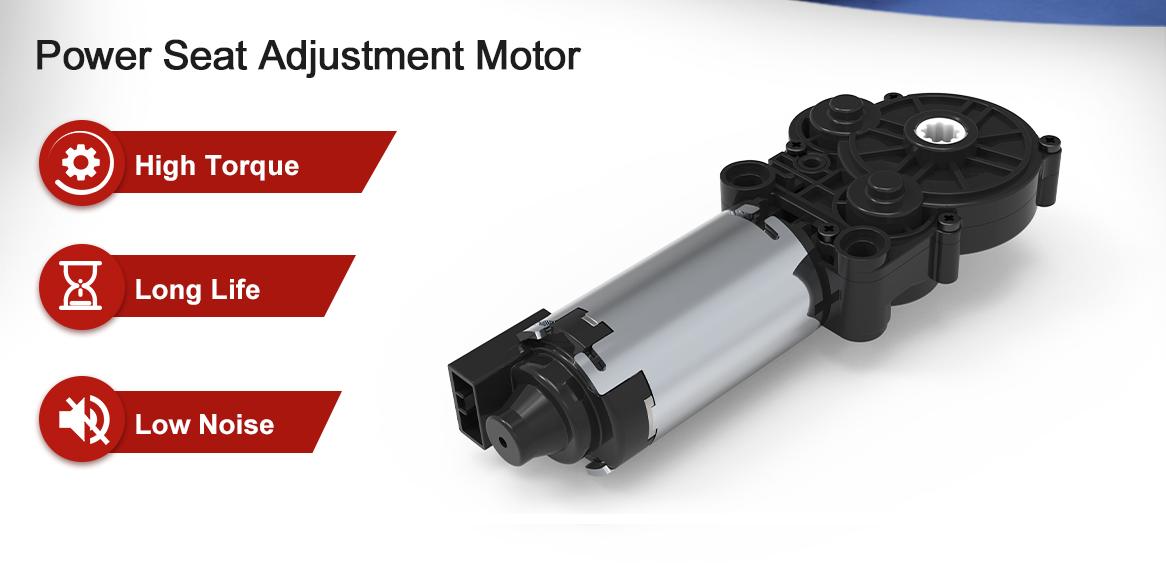

Picture shown: quiet electric motor for seat adjustment

How to Make Quiet Electric Motors in Cars

Creating a silent electric motor is a challenge of NVH (Noise, Vibration, and Harshness) engineering. It requires addressing noise at its source—whether mechanical, electromagnetic, or aerodynamic.

Here are the eight critical factors that contribute to whisper-quiet operation.

1. Brushless Technology

The most significant leap in noise reduction comes from the transition to brushless DC (BLDC) technology. Traditional brushed motors rely on physical carbon brushes making contact with a commutator to switch current. This mechanical friction creates audible buzzing and electrical sparking.

Brushless DC Motors eliminate this physical contact entirely. By using electronic commutation, BLDC motors remove the primary source of mechanical friction noise.

Furthermore, they eliminate the "brush noise" associated with wear debris accumulation, ensuring that the motor remains quiet throughout its operational lifespan.

At Power Motor, we have utilized this advantageous technology. For example, our high-end automotive electric seat BLDC motor solution is designed to operate below 35 decibels—so quiet it is virtually inaudible in a moving car.

2. Advanced Bearing Technology

Bearings are the interface between stationary and rotating parts and play a crucial role in acoustic control. To achieve a low-noise electric motor, manufacturers utilize high-precision ball bearings or sintered bronze sleeve bearings with optimized lubrication.

High-quality bearing systems reduce friction and stabilize the rotor shaft, preventing radial movement that can cause vibration and audible rattling, especially at high speeds. Typical applications include wiper and window lift motors.

For instance, Power Motor employs a unique bearing structure for our wiper motor solutions for construction and agricultural vehicles. The design features high-pressure resistance and a low friction coefficient, which is aimed at efficiency improvement and noise reduction.

3. "Skewed Slot" Design

One of the subtle sources of noise in electric motors is "cogging torque," which is particularly noticeable in low-speed applications. It occurs when the magnetic attraction between the rotor magnets and the steel teeth of the stator creates a jerky, "stepped" motion rather than a smooth rotation. This vibration manifests as a hum.

A "skewed slot" design is a highly effective hardware technique for reducing cogging torque and torque ripple during operation. This involves twisting the rotor laminations or stator slots along the motor's axial direction to spatially average out slot harmonic effects.

Advanced manufacturers optimize this using 3D finite element (FE) simulation, employing step-skew or herringbone (V-shaped) patterns to balance electromagnetic benefits with mechanical load for smooth, quiet rotation.

4. Optimized Gear Geometry

Many automotive applications, such as power tail doors, rely on gear motors to multiply torque. However, gears are a common source of "gear whine" due to transmission errors (TE).

High-quality gear motors employ advanced gear geometries. This includes the use of worm gears for self-locking applications or helical gears, which offer smoother engagement than spur gears.

Furthermore, manufacturers optimize the gear tooth profile—sometimes using asymmetric designs—to minimize the dynamic mesh force. This ensures that the gears roll smoothly against one another rather than impacting, significantly reducing mechanical noise.

5. Material Science

The materials chosen for the motor's housing and internal components play a critical role in sound dampening. High-quality motors utilize specialized damping materials and high-grade composites that absorb vibration rather than transmitting it to the vehicle's frame.

For instance, replacing metal gears with high-strength engineering plastics in lower-torque applications can significantly soften the sound profile of the motor operation.

6. Precision Manufacturing

Even the best design will be noisy if the manufacturing tolerances are loose. Mechanical imperfections, such as rotor imbalance or stator misalignment, act as amplifiers for vibration.

Rigorous dynamic balancing of the rotor prevents excessive force on bearing assemblies, extending component life and maintaining acoustic quality. Controlling dynamic eccentricity ensures consistent radial forces, meeting the quiet electric motor standards required by top-tier automotive brands.

7. Pulse Width Modulation (PWM)

Noise isn't just mechanical; it can be electrical. The way a motor controller switches power on and off can create audible frequencies (the "whine" of an electric drill).

Modern motor control systems utilize advanced pulse width modulation (PWM) techniques with high switching frequencies. By pushing the switching frequency above 20 kHz—the upper limit of human hearing—the electrical operation of the motor becomes silent to the human ear.

This is critical for HVAC blowers and other motors that run continuously while driving.

8. Soft Start/Soft Stop Algorithms

Sudden jerks create noise and vibration. If a window regulator slams the glass into the frame or a seat motor jerks into motion, it creates a "clunk." Soft start/stop algorithms use solid-state components to gradually ramp up voltage and torque. It allows the mechanical components to engage smoothly, eliminating mechanical shock and transient noise.

Partnering with an Experienced Automotive Motor Manufacturer

For automotive OEMs and suppliers, achieving industry-leading NVH performance requires a partner with deep expertise in both electromechanical design and precision manufacturing.

With more than 20 years of experience in motor customization engineering, Power Motor has accumulated a massive prototype database specifically for automotive applications. Our R&D team works closely with vehicle manufacturers to customize quiet electric motors, controlling every variable from material science to control algorithms.

Whether it is a 30 mm seat motor or a high-torque tailgate strut, we understand the rigorous demands of the modern automotive industry.

Conclusion

In today’s automotive cabins, a quiet electric motor is no longer optional—it defines perceived quality. Achieving low-noise performance demands advanced design, precision manufacturing, and deep NVH expertise.

Power Motor combines all three to deliver proven, automotive-grade solutions. If your next project requires reliable, low-noise performance, contact Power Motor to discuss a customized motor solution!