What Are the Best Electric Motors for Robotics?

Electric motors are the heart of robotics, transforming electrical energy into mechanical motion that drives robot movement, manipulation, and functionality. Selecting the right motors for robotics is crucial to ensure they perform efficiently, accurately, and reliably.

As an experienced motor manufacturer, Power Motor will explore the best electric motors for robotics by examining common types, key features, and the ideal motor choices for various robotic applications.

Common Types of Motors for Robotics

Robotics predominantly relies on DC motor variants, as they are easily controlled by battery power and offer excellent control over speed and torque. Broadly speaking, the three primary robotic motor types are DC motors, stepper motors, and servo motors.

1. DC Motors

Simply put, there are brushed and brushless DC motor options. Brushed DC motors can be said to be the simplest and most cost-effective electric motors for robots. They provide good starting torque and are easy to control.

However, the brushes and commutator create friction, leading to wear, acoustic noise, and lower efficiency. This makes them suitable for simple, low-cost applications where high efficiency and long life are not paramount.

In comparison, BLDC motors for robots offer superior efficiency, longer lifespans, higher speeds, and a better power-to-weight ratio by eliminating the brushes. They are also more complex to control, requiring an Electronic Speed Controller (ESC), but the performance payoff is substantial. Small BLDC motors with high efficiency, for instance, are particularly favored in applications like drones.

Product shown: Industry Automation BLDC Motor

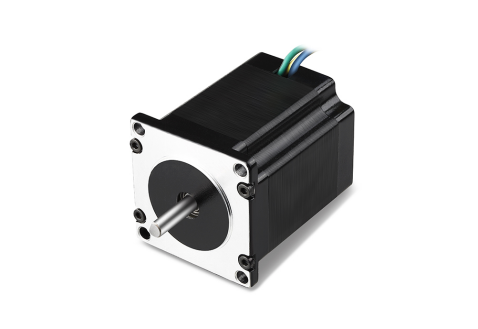

2. Stepper Motors

Stepper motors excel at open-loop position control. They rotate in discrete "steps" and can be commanded to move to a specific angle without a complex feedback system. This makes them ideal for applications requiring very precise, repeatable positioning and holding torque at zero speed, such as 3D printing, CNC machines, and camera platforms.

Their main limitation is a reduction in available torque at higher speeds or under heavy loads. Encoders can be added to stepper motor systems to create more accurate, closed-loop positioning systems. While adding these feedback devices increases overall system cost, it is generally still less expensive than switching to a full servomotor solution.

3. Servo Motors

A servo motor is a closed-loop system, which means it integrates an electric motor (often DC or BLDC) with a position sensor (encoder) and a control circuit. The controller constantly receives feedback and adjusts the motor to precisely maintain a commanded position, speed, or torque.

This inherent closed-loop control makes servo motors the gold standard for high-precision, high-dynamic robotic applications like multi-axis robotic arms, where accurate and fast position control is essential.

Best Electric Motors for Various Robotics Applications

Though there are different motors for robotics, the optimal motor choice is heavily dependent on the robotic task. Matching the motor type to the application ensures maximum efficiency and performance. Some common cases are:

- Drones and Compact Robots (e.g., Handheld Inspection Devices): Here, weight and power efficiency are critical. Small BLDC motors with high efficiency and an excellent power-to-weight ratio are highly recommended. Their reliability and lack of brush-related maintenance are major advantages for airborne or sealed systems.

- Industrial Robotic Arms (Multi-Axis Manipulation): These require highly dynamic, precise, and responsive movement. Servo motors (often high-performance AC or DC brushless types) are the best choice. They provide the necessary closed-loop feedback for smooth, precise motion and high torque density.

- Mobile Robots and Wheeled Platforms (e.g., AGVs, Service Robots): These typically require sustained torque at varying speeds. Geared brushed DC motors or mid-sized brushless DC motors are common. The choice often balances cost (BDC) against longevity and efficiency (BLDC).

- High-Precision Linear Movement (e.g., 3D Printers, Scanners): Stepper motors shine here due to their inherent ability to hold a position without a separate feedback mechanism and their high positional resolution.

Factors to Consider When Choosing a Motor for Robotics

The above talks about the general rule. For your specific robots, you can make your choice by balancing the following technical and practical factors.

1. Torque and Speed Requirements

This is the most fundamental factor. You must determine the required output torque and maximum speed for your application. A high-torque, low-speed application (like a heavy lift) will favor a geared solution, while high-speed motion (like a drone propeller) requires a high-RPM motor.

2. Precision and Control Needs

Does your robot need to move to a precise position (e.g., ±0.1°)? If so, a servo or micro-stepped stepper motor is necessary. For simple speed control, a standard BDC or BLDC motor may suffice.

3. Power Consumption and Energy Efficiency

For battery-powered or mobile robots, efficiency is paramount to maximize runtime. BLDC motors are inherently more energy-efficient than brushed alternatives.

4. Size, Weight, and Mounting Options

In compact or airborne systems, every gram counts. Coreless DC motors and high-density BLDC motors offer powerful solutions in a small form factor. Ensure the motor's physical dimensions and mounting interface match your robot's mechanical design.

5. Budget Considerations and Maintenance Requirements

BDC motors and stepper motors often have a lower upfront cost. At the same time, BLDC motors for robot applications offer a much longer, maintenance-free operational life, which can significantly reduce long-term ownership costs, making them more economical over time.

Power Motor: Expert in Motor Customization for Robotics and More

With 20+ years of expertise, Power Motor is a premier designer and manufacturer of high-precision electric motors, specializing in DC motors, AC motors, geared motors, stepper motors, and more.

We offer customized motor solutions. In the field of robotics, you can rely on our professionalism to have the right robotic motors that match your application's required speed, torque, efficiency, and size.

In addition, our capabilities extend well beyond robotics—we also have extensive experience supplying motors for home appliances, medical equipment, automotive applications, office automation, power tools, and more.

Conclusion

The advancement of robotics hinges on the performance of its motion components. The decision of "What are the best electric motors for robotics?" is not about a single answer but about correctly evaluating the trade-offs between DC, stepper, and servo motors based on your specific needs for torque, precision, and efficiency.

For cutting-edge projects and demanding applications, customization is the key to unlocking peak performance. If you need any further advice, contact Power Motor today to discuss your unique robotic motor requirements, and we can help provide a decisive competitive advantage in your field!