How Power BLDC Motor Are Reshaping the Modern Vacuum Cleaner Market

How Power BLDC Motor Are Reshaping the Modern Vacuum Cleaner Market

In today's pursuit of efficient, convenient, and high-quality living, vacuum cleaners have long become essential cleaning appliances for many families. The evolution of their core power source, particularly the widespread application of Brushless DC Motors (BLDC), represents a silent yet profound technological revolution, thoroughly reshaping product forms and user experience.

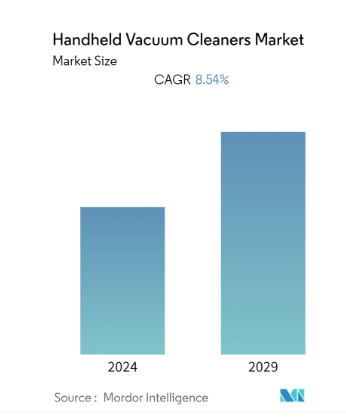

I. Vacuum Cleaner Market: Robust Growth and Diversification Trends

The global vacuum cleaner market continues to show a growth trend. With consumption upgrading and increasing demand for healthy home environments, vacuum cleaner products exhibit two main trends: firstly, the comprehensive popularization of cordless stick vacuums, whose lightweight and flexible characteristics have made them the absolute mainstream in the market; secondly, the rapid development of intelligent robotic vacuum cleaners, integrating sweeping, suction, mopping, and self-cleaning, freeing users' hands.

The market's potential lies not only in new users but also in product upgrades. Consumers are no longer satisfied with "usable" products but pursue those that are "easy to use," "durable," and "smart." This higher-level demand directly places unprecedented stringent requirements on the "heart" of the vacuum cleaner—the motor.

II. Market Pain Points: The Performance Limitations of Traditional Motors

Before Brushless DC motors became mainstream, vacuum cleaners mostly used traditional brushed motors or lower-performance brushless motors. These solutions struggled to meet the new market demands, primarily due to the following major pain points:

1.The Suction Power vs. Runtime Dilemma: For cordless vacuums, strong suction power means higher power consumption, which quickly depletes the battery, significantly reducing runtime. Users were forced to make difficult trade-offs between "power mode" and "endurance mode."

2.Excessive Noise: During operation of traditional brushed motors, physical friction and electrical sparking occur between the brushes and commutator, not only generating unpleasant high-decibel noise that disturbs people rest but also causing mechanical wear that limits motor life.

3.Low Energy Efficiency: Brushed motors waste significant energy on brush friction and heat generation, with conversion efficiency generally below 50%. This not only wastes electrical energy but also directly translates to shorter runtime in cordless products, while the generated heat requires additional thermal management design.

4. Lifespan and Reliability Issues: Brushes, as wearable components, inevitably wear out after prolonged use, leading to decreased motor performance or even failure, accompanied by high maintenance costs. For home appliance products designed to last for years, this is a critical weakness.

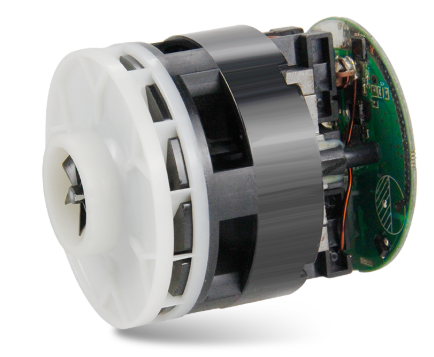

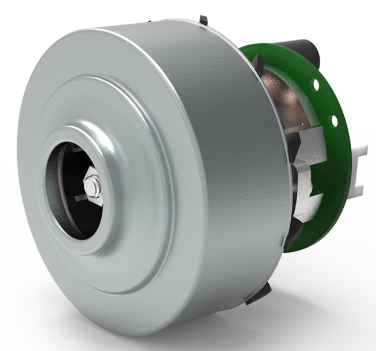

III. Power Motor: High-Performance Brushless DC Motor Solutions

Addressing the above pain points, Power Motor’s new generation of high-performance Brushless DC motors, coupled with advanced control technology, provides perfect solutions and has become the standard for high-end vacuum cleaners.

1.High-Efficiency Conversion, Solving the Runtime Problem: BLDC motors use electronic commutation, completely eliminating friction losses caused by brushes. Their energy conversion efficiency can reach over 80%. This means that consuming the same battery power, a brushless motor can output stronger power, generating greater suction. Alternatively, it can significantly extend runtime while maintaining the same suction power. Advanced motor control systems (ESCs) can intelligently adjust motor speed based on the cleaning scenario, automatically switching power between carpets and hard floors to maximize energy efficiency.

2. Balancing Super Power and Quiet Operation: The speed of brushless motors can easily exceed 100,000 RPM, a level difficult for traditional brushed motors to achieve, laying the foundation for generating super suction. Simultaneously, as the physically contacting commutation structure is eliminated, their operational noise primarily comes from aerodynamic noise (wind sound) rather than mechanical noise, resulting in superior overall sound quality. Through precise motor design, dynamic balance correction, and airflow path optimization, modern vacuum cleaners can provide powerful suction while maintaining a relatively quiet operating environment.

3. Intelligent Control, Long Life, and High Reliability: Brushless motors must be driven by a controller, giving them an inherent "smart" gene. The main MCU can monitor motor load, speed, and temperature in real-time, enabling advanced functions such as:

· Load Sensing: Automatically detects if the floor brush is tangled with hair or the intake is clogged, adjusting power or issuing an alert promptly to protect the motor.

· Constant Power Output: Even as battery voltage drops during use, the control system can adjust the current to maintain the motor's rated power operation, ensuring suction power remains consistent without decaying.

· Seamless Integration: Interacts with other sensors in the machine (e.g., LIDAR, dirt detection) to build a truly intelligent cleaning system.

Since there is no brush wear, the bearings become the main wearing components, and their lifespan far exceeds that of brushes. This makes the overall lifespan of brushless motors typically several times that of traditional motors, greatly enhancing reliability.

IV. The deep application of Power Motor Brushless DC motors in the vacuum cleaner field has truly unlocked the product's potential.

It solves the core pain points of cordless vacuums—suction, runtime, and noise—and elevates the user experience to new heights through intelligent control.

Shenzhen Power Motor Co., Ltd has an experienced sales and R&D teams to provide reliable, cost-effective solutions tailored for your product. We collaborate closely to bring your product to market successfully.

Contact Us Today:

�� Tel: +86-755-3689 9898 / 400-622-3329, ✉ Email: info.power@power-motor.com

Note: This article is contributed by sales department