What is the Electric Motor Controller?

Electric motors are essential to modern industry, powering everything from factory equipment to home appliances. But to operate efficiently and safely, they require precise control. That's where the electric motor controller comes in.

This device governs motor functions such as speed, torque, and direction, ensuring optimal performance. At Power Motor, we specialize in integrated electric motor and controller solutions. In this article, we'll explain what an electric motor controller is, how it works, and where it's used.

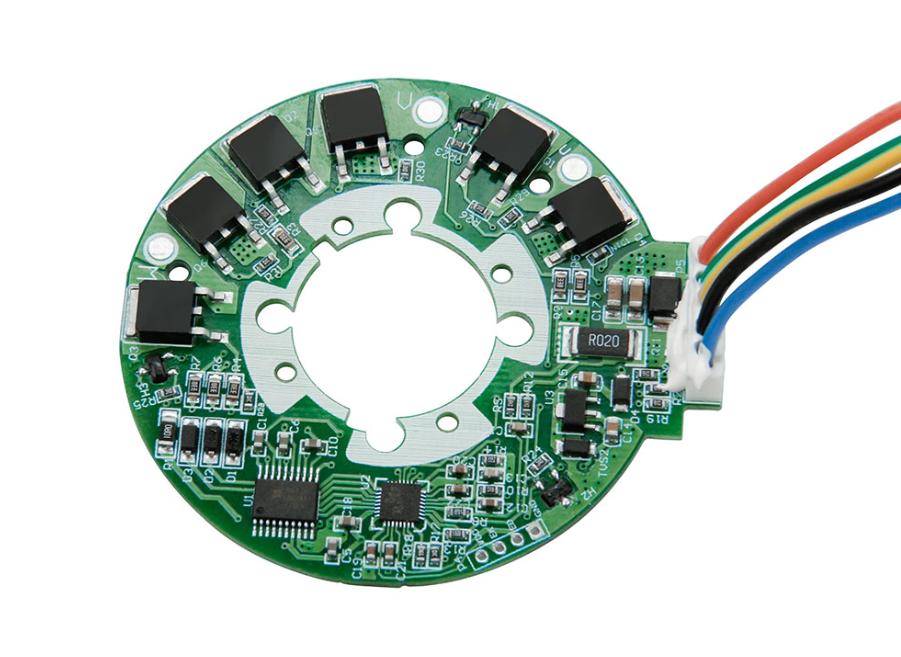

Picture shown: a brushless DC motor controller for fascia gun muscle massager

What is an Electric Motor Controller?

An electric motor controller is an electronic device or system that governs the performance of an electric motor. It manages key operations such as starting and stopping the motor, regulating speed and torque, and ensuring safe operation under varying load conditions. The controller receives input from the user or system and adjusts the motor's performance accordingly.

At its core, a motor controller serves to optimize the motor's operation for energy efficiency, responsiveness, and longevity. Whether in electric vehicles or home appliances, the controller is the brain that makes motor systems smarter and more reliable.

Main Components of an Electric Motor Controller

An electric motor controller is made up of several essential components that work together to regulate motor function:

l Controller: This is the computational core that processes input signals and determines motor behavior. It often includes microcontrollers, digital signal processors (DSPs), or programmable logic controllers (PLCs), depending on the complexity of the application.

l Power Electronics: These components, such as transistors, thyristors, and Insulated Gate Bipolar Transistors (IGBTs), handle the switching and modulation of electrical energy. They are crucial for adjusting the voltage and current supplied to the motor.

l Sensors: Different sensors, such as speed sensors, position encoders, current sensors, and temperature sensors, feed real-time data to the controller. This feedback enables accurate and adaptive motor control.

l Communication Interfaces: Modern systems often require integration with broader control networks. Protocols like Modbus, CAN, and Ethernet allow motor controllers to communicate efficiently with external systems or devices.

l Protection Devices: To ensure safety and prevent damage, motor controllers are equipped with safety components, like fuses, circuit breakers, and overload relays. These components protect against overcurrent, overheating, and other electrical faults.

Types of Electric Motor Controllers

There are various types of motor controllers, each tailored to the characteristics of the motor it controls and the application it serves.

l AC Motor Controllers: These controllers manage alternating current motors and typically include variable frequency drives (VFDs) to adjust speed and torque dynamically. They're widely used in HVAC systems, industrial machines, pumps, and beyond.

l DC Motor Controllers: Designed for direct current motors, these controllers regulate voltage and current using methods such as pulse-width modulation (PWM) and linear control. They are often found in robotics, automotive systems, portable devices, and others.

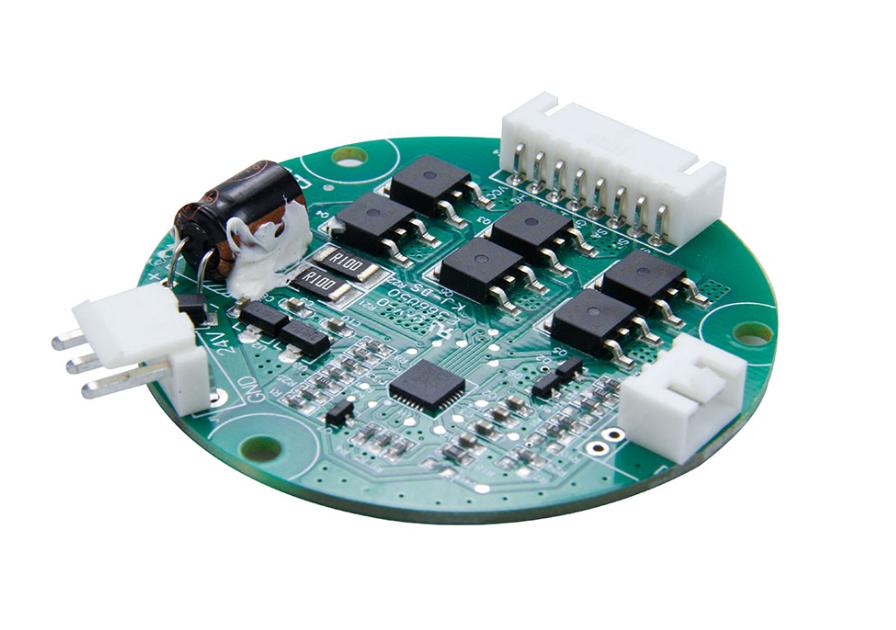

Picture shown: a 3 phase brushless DC motor controller for blower

Each type has unique control algorithms and hardware requirements, but both share the goal of ensuring optimal motor operation.

Applications of Electric Motor Controllers

The electric motor and controller combination is used across numerous industries and applications. Here are a few of the most common:

l Industrial Automation: Motor controllers play a crucial role in industrial automation by precisely controlling the motion and speed of equipment such as conveyor belts, packaging systems, robotic arms, pumps, and fans. This ensures efficient, safe, and reliable manufacturing processes.

l Electric Vehicles: In electric vehicles, motor controllers help precisely manage vehicle start-up, acceleration, braking, and regenerative energy recovery, enhancing energy efficiency and driving experience while providing fault diagnosis and protection for safety.

l Home Appliances: Many household appliances—such as refrigerators, washing machines, vacuum cleaners, blenders, and air conditioners—use motor controllers to drive their internal motors. This enables efficient, energy-saving, and stable operation, for example, controlling wash and spin cycles in washing machines.

l Consumer Electronics: Motor controllers are also applied in consumer electronics like robots, toys, and office equipment, offering precise control over motor speed, torque, and direction to improve product performance and user experience.

At Power Motor, we've been proud to support different sectors with reliable motor controller solutions that are tailored to specific customer needs.

Why Choose Power Motor?

With decades of experience in electric motor development and control technologies, we at Power Motor offer fully integrated solutions that combine high-quality electric motors with advanced motor controllers. Our team works closely with clients to design customized systems that optimize performance, safety, and cost efficiency.

Whether you're in need of a compact solution for consumer electronics or a robust system for industrial machinery, our electric motor controllers are built to perform under pressure. You can explore our offerings and request personalized solutions directly through our website.

Conclusion

In summary, an electric motor controller is a critical component that ensures efficient, safe, and responsive operation of electric motors. From adjusting speed and torque to providing system protection and communication, its role cannot be overstated.

We at Power Motor are here to offer the best-fit motor and controller solution for your specific application. You can rely on our professional solutions to achieve precise control, greater energy efficiency, and superior reliability in your systems. Contact us today to learn more about our custom-tailored motor solutions!