What is a Worm Gear Motor?

Have you ever needed a motor that delivers powerful, slow rotation in a tight space—something that can hold its position even when power is off? That's exactly where worm gear motors shine. These compact and efficient solutions are widely used in applications requiring high reduction ratios, which means high torque at low speeds.

At Power Motor, we specialize in high-performance gear motors, and in this article, we're providing a detailed look at what a worm gear motor is, how it works, why it's beneficial, and how to choose the right one for your needs.

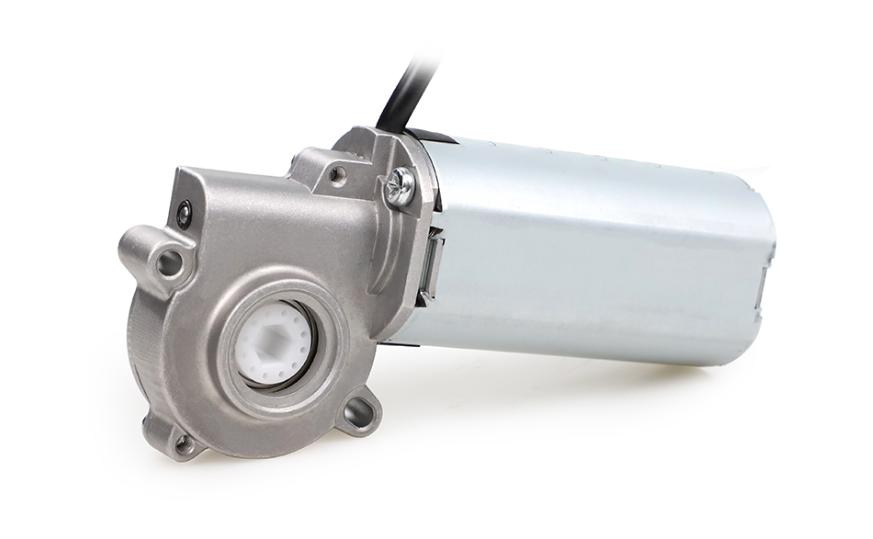

Picture shown: a worm gear motor for adjustable standing desk

What is a Worm Gear Motor?

A worm gear motor is a gear motor type that uses a worm (a screw-like gear) meshing with a worm wheel (a gear wheel) to transmit motion and power. The worm is typically the driving component connected to the motor shaft, and the worm wheel is mounted on the output shaft. This setup is highly effective at producing significant torque with minimal space usage, making it ideal for compact and high-load applications.

How Does a Worm Gear Motor Work?

In a worm gear electric motor, the motor drives the worm, which then rotates the worm wheel. The unique tooth engagement between the worm and wheel allows for large gear reductions in a single stage.

Due to the angle of the worm's threads, the motion is transferred smoothly and gradually, enabling precise control. In most configurations, the worm can drive the wheel, but the wheel cannot drive the worm—resulting in a built-in self-locking mechanism.

Key Advantages & Benefits of Worm Gear Motors

l High Torque Output

Worm gear motors are known for delivering exceptional torque even at low speeds. This makes them ideal for lifting, moving, or positioning heavy loads.

l Compact Design

Thanks to the worm-and-wheel arrangement, you get a lot of power in a small footprint. This is perfect for space-constrained applications.

l Self-Locking Capacity

One of the key advantages of a worm gear motor is its self-locking feature, which prevents back-driving—adding safety and reliability, especially in lifting and hoisting scenarios.

l Smooth & Quiet Operation

Worm gear motors operate with less vibration and noise compared to other gear systems. This makes them well-suited for environments that prioritize quiet operation.

l Durability & Reliability

Due to fewer moving parts and the sliding contact nature of worm gears, these motors are generally long-lasting and require less maintenance.

l Variety of Gear Ratios

Worm gear motors can achieve very high gear reduction ratios in a single stage. This allows precise control of speed and torque to meet diverse application requirements.

Applications of Worm Gear Motors

Here are some typical application cases of worm gear motors.

l Material Handling: Widely used in conveyors and loaders where consistent, low-speed torque is necessary.

l Lifting & Hoisting Equipment: Ideal for cranes, jacks, and elevators due to their high torque and self-locking features.

l Automotive: Useful in applications such as seat actuators, mirror adjusters, and tailgate lifts where compact, low-speed motion is required.

Picture shown: a power seat adjustment motor

l Robotics: Provides controlled, smooth, and precise movement for robot arms and servos, thanks to their high torque density and compact design.

l Food Processing: Stainless steel and sealed versions of worm gear motors meet hygiene standards while delivering reliable power to run food industry machinery.

l Home Applications: Common uses include gate openers, adjustable beds, and recliners, where quiet operation, compactness, and self-locking features are advantageous.

Factors to Consider When Choosing a Worm Gear Motor

When selecting the right worm gear electric motor for your application, here's what to keep in mind:

l Required Torque and Speed

Determine the torque and speed needed to drive your load effectively. The motor must provide sufficient starting and running torque while matching the desired output speed to avoid underperformance or damage.

l Gear Ratio

The gear ratio affects speed reduction and torque multiplication. Selecting the right ratio balances performance, efficiency, and cost.

l Duty Cycle

Consider whether the motor will operate continuously or intermittently. Continuous operation demands motors with good thermal management and durability, while intermittent use allows for less stringent requirements.

l Operating Environment

Environmental factors such as moisture, dust, temperature, and corrosive elements influence material choice and sealing. For harsh conditions, opt for motors with high protection ratings, stainless steel components, or sealed designs to ensure reliability.

l Mounting Configuration

Verify that the motor's size, shaft orientation, flange type, and mounting holes fit your equipment. Worm gear motors are compact and versatile but must be compatible with your system's physical constraints.

l Efficiency

Due to sliding friction, worm gear motors generally have lower efficiency than other gear types. Consider the trade-off between efficiency, energy consumption, heat generation, and cost when selecting the motor.

Power Motor: Your Worm Gear Motor Specialist

At Power Motor, we bring over 20 years of experience in custom motor solutions, including a full lineup of worm gear motors. We offer expert guidance and tailored engineering to meet your specific requirements—whether you need a standard model or a fully customized solution for complex machinery.

Our team is here to support you from design to production, ensuring that every worm gear motor delivers optimal performance, durability, and value. You can explore our product range and consult with our engineers directly on our website.

Conclusion

In summary, a worm gear motor is essential in many industries due to its high torque, compact design, self-locking ability, and quiet performance. Whether you're designing equipment for material handling, automation, or home applications, a worm gear electric motor provides a reliable and efficient solution.

At Power Motor, we're committed to helping you find or develop the right worm gear motor, such as a DC worm gear motor, for your project. Reach out to us today for a custom consultation and discover how our expertise can power your innovation!