Sustainable Design Power Motor's Role in Maximizing the Scrap Potential of Electric Motors

The growing global focus on circular economy principles means that an electric motor’s lifecycle shouldn't end when it reaches obsolescence. For Original Equipment Manufacturers (OEMs), designing for sustainability includes maximizing the motor's scrap value, recovering valuable raw materials, and minimizing environmental impact. Choosing a responsible electric motor supplier is key to this process. At Power Motor, we integrate end-of-life considerations into the initial design phase, ensuring our products offer maximum recoverable material value, benefiting both the environment and our clients' bottom lines.

Designing for Recovery The High Value of Copper and Steel

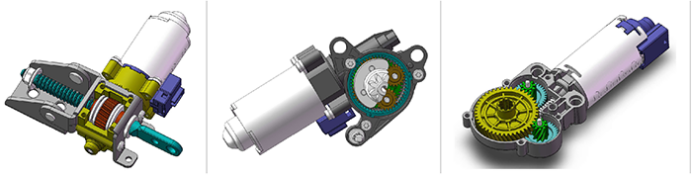

The scrap value of an electric motor is predominantly determined by the mass and purity of its component materials, primarily copper and steel. The copper found in the stator and armature windings is highly valuable and easily recyclable. Similarly, the steel used in the motor housing and magnetic circuits can be melted down and repurposed. As a forward-thinking electric motor supplier, Power Motor prioritizes designs that simplify the separation of these materials. For instance, our construction methods minimize the use of non-recyclable adhesives and plastics, ensuring that both brushed and brushless dc motor products yield the cleanest possible scrap streams when processed at specialized facilities.

The Brushless Motor Advantage in Scrap Potential

The move toward advanced motion technology also influences scrap value. While traditional brushed motors rely on copper windings, the increasingly complex magnetics in modern brushed and brushless dc motor technology present new opportunities. Permanent Magnet DC (PMDC) and BLDC motors utilize high-strength magnets, often containing rare earth elements (like Neodymium), which, while requiring specialized recycling, represent a high-value asset. Power Motor's commitment as an expert electric motor supplier includes material traceability, which aids recyclers in efficiently isolating these magnets, further boosting the potential scrap return. Furthermore, the electronic components integrated into a brushless motor offer additional recoverable materials, distinguishing them from simpler brushed designs.

Power Motor's Commitment to the Circular Economy

At Power Motor, sustainable design means engineering high-performance motors that last longer and are easier to dismantle when their service life is complete. We believe the future of manufacturing involves taking responsibility for the full product cycle. By meticulously designing both brushed and brushless dc motor solutions for material purity and easy deconstruction, we provide OEMs with a valuable, traceable asset, not just an electronic component. This commitment to circularity makes Power Motor more than just a manufacturer; we are a partner in your sustainability goal