Optimize Your System: Power Motor's Guide to Eliminating Gearbox Inefficiency and Complexity

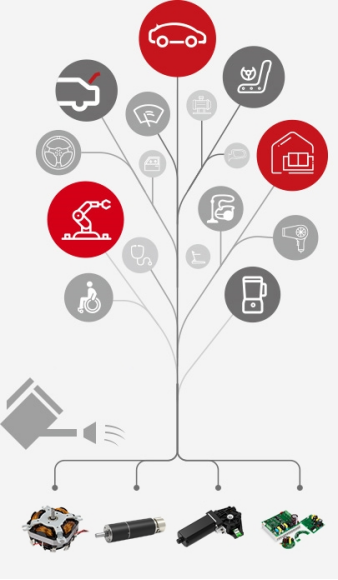

For many applications, the prevailing design standard includes an electric motor coupled to a motor with gear box to achieve the necessary speed reduction and torque multiplication. While this approach is traditional, it introduces inherent inefficiencies and mechanical complexity that can hinder modern high-precision systems. For OEMs focused on maximizing efficiency and reliability, the path forward is often to eliminate the gearbox entirely. This shift requires leveraging the specialized design capabilities of a dedicated brushless motor manufacturer.

The High Cost of the Conventional Motor with Gear Box

A standard motor with gear box creates system inefficiencies in several ways. First, every mechanical component—from the gears themselves to the bearings and seals—contributes friction, resulting in significant energy loss, often reducing overall system efficiency by 10% or more. Second, a motor with gear box introduces backlash, wear points, noise, and requires periodic lubrication and maintenance. These factors directly contribute to increased Total Cost of Ownership (TCO) and reduce operational lifespan, making it a liability in mission-critical environments. To avoid these drawbacks, a bespoke direct-drive solution is the superior engineering choice.

Customizing Torque: The Brushless Motor Manufacturer Solution

Eliminating the need for a gearbox starts with the motor design itself. Instead of relying on external mechanical reduction, Power Motor, as a leading brushless motor manufacturer, custom-engineers the motor's electromagnetic properties—specifically the winding design and magnet geometry—to produce high torque directly at the required operating speed. By increasing the number of magnetic poles and optimizing winding inductance, we can create a low-speed, high-torque output that meets the application's needs without mechanical assistance. This direct-drive approach simplifies the system, drastically reduces friction losses, and eliminates the common failure points associated with a traditional motor with gear box.

Power Motor’s Integrated Approach to Gearless Design

As a premier brushless motor manufacturer, Power Motor provides integrated design services that look beyond the motor itself. For a gearless system to succeed, the control electronics are paramount. We pair our high-torque motors with custom-tuned controllers that provide precise current management and advanced feedback loops. This ensures the motor maintains smooth, accurate speed and torque, even at very low RPMs, without the jerkiness or instability that often plagues systems attempting to eliminate the motor with gear box using generic drives. By optimizing the complete system—electromagnetics, winding, and control—Power Motor helps OEMs achieve unparalleled precision, reduced acoustic noise, and dramatically improved system efficiency. Choosing a partner with proven expertise as a dedicated PMDC motor manufacturer is essential for making the shift to gearless, high-performance motion.