What are Different Types of Electric Motors for Fans?

Electric motors are at the heart of every fan, playing a crucial role in converting electrical energy into mechanical motion to circulate air effectively. They impact the fan's speed, airflow, noise level, and energy consumption.

Fan manufacturers need to select the appropriate electric motors for fans so that they can offer products that meet customer expectations. On this page, Power Motor will introduce various types of motors used in fans and provide insights into how they differ from each other!

Different Electric Motors for Fans

Generally, there are two types of fan electric motors, namely, the AC electric fan motor and the DC electric fan motor.

1. AC Electric Motors for Fans

AC motors are traditional electric motors for fans. They are powered by alternating current and are known for their durability and reliability.

l Single-phase Induction Motors

Single-phase induction motors are commonly seen in household and small fans, like table fans and ceiling fans. They operate on single-phase alternating current and are ideal for low-power applications. Basically, they are compact, cost-effective, and relatively simple to maintain. With an easy start-up mechanism, they are capable of providing consistent, steady airflow.

l Three-phase Induction Motors

Three-phase induction motors are typically used in larger industrial fans that require high power and efficiency. Some examples are ventilation systems, HVAC applications, and large industrial fans. These motors operate on three-phase alternating current and are capable of handling heavier loads with higher reliability.

Compared to single-phase motors, three-phase motors usually feature high energy efficiency and are designed to be robust enough for continuous operation under harsh conditions.

2. DC Electric Motors for Fans

DC fan motors are applied for fans with built-in batteries or external DC power supplies. Their outstanding features, like higher efficiency, make them increasingly popular in modern fan designs, especially in energy-efficient and compact models.

l Brushed Motors

Brushed motors use a commutator and brushes for electrical communication. They require more maintenance or brush replacement due to the mechanical friction between these two featured components. Compared to their brushless counterparts, they are more affordable and easy to control, making them ideal for applications that are sensitive to initial costs. Some applications are handheld small fans and simple ventilation equipment.

l Brushless Motors

As the name suggests, brushless DC (BLDC) motors do not have brushes, which reduces wear and tear and improves the motor's lifespan. Specifically, they are known for their higher energy efficiency, reduced noise, and better speed control. These features make them suitable for use in industrial appliances, medical equipment, data centers, and more.

Product shown: Ultra low noise floor fan motor 24V BLDC motor outer rotor PBL5210 Series

3. AC vs. DC Electric Motors for Fans: A Comparison

l Energy Efficiency

AC motors, especially single-phase models, are typically less efficient than DC motors. DC motors, especially brushless ones, are designed to deliver higher efficiency with lower power consumption.

l Performance

AC motors are generally more robust and capable of delivering consistent power, making them ideal for large industrial fans. Meanwhile, DC motors offer better speed control and smoother operation, which is a major benefit for residential fans.

l Cost

AC motors, especially in single-phase configurations, are typically more affordable than DC motors. DC motors, particularly brushless ones, tend to cost more due to their improved structural design and higher efficiency.

l Maintenance

AC motors generally require less maintenance than DC motors with brushes. Further, as there is no brush component, brushless DC motors have the advantage of requiring minimal maintenance.

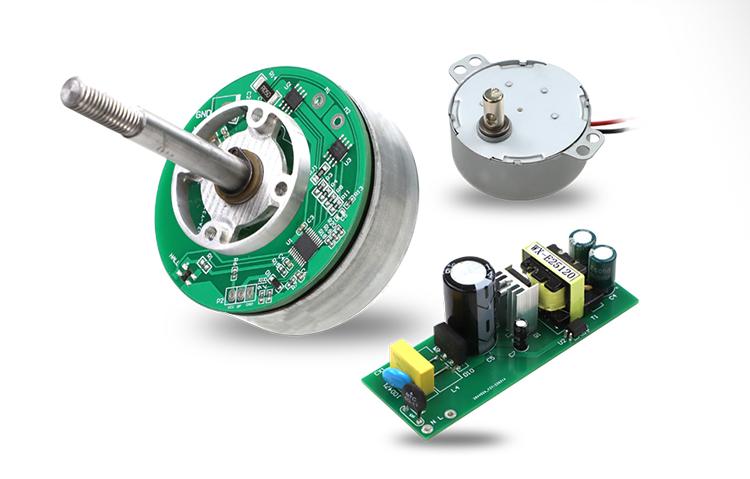

Power Motor's BLDC Motors for Fans

Power Motor is a professional motor manufacturer that has 20+ years of expertise. We understand that the continuously operating fans require a high-efficiency motor to help save energy. Moreover, lower noise levels and flexible air speed control are important in different usage scenarios and for different user needs.

That's why Power Motor focuses on electric fan brushless DC motor solutions. They aim to offer more efficient and quieter operation within a more compact design. Furthermore, different from traditional AC fan motors that offer common 3- or 4-speed options, BLDC fan motors can adjust the speed at will, offering a more comfortable user experience.

Conclusion

Choosing the right electric motors for fans is critical for performance and efficiency. With different highlights, AC and DC fan motors are widely applied in different scenarios, like being utilized as ceiling fan motors or industrial fan motors.

Contact Power Motor if you are looking for fan motors that provide an excellent balance of energy efficiency, durability, and performance. We also offer industry-leading OEM/ODM services for fan manufacturers to have their perfect products!