Electric Clothes Drying Rack Motor Solution

With the rapid development of the national economy, human requirements for home life are becoming higher and higher, from a "survival-type" to an "enjoyment type". Various household appliances that facilitate life have emerged, and electric clothes drying racks are gradually replacing the original Fixed drying racks and hand-operated lifting drying racks, the popularity rate is getting higher and higher. And with the increase in China's urbanization rate and the rapid expansion of real estate, the market for electric drying racks continues to rise. As the core of electric drying racks Components, motors are naturally the hegemony of major manufacturers.

At present, as long as the drying rack motor on the market is a pull-type DC permanent magnet motor, the motor is used to drive the winding wheels of 2 worm wheels to pull the clothes rail up and down. The main problems are as follows:

1. The volume is large, the weight is heavy, and the thickness of the main box of the drying rack is limited.

2. Due to the use of worm gears as self-locking means, the actual transmission efficiency is low. The motor has large working power and a large current. Therefore, the maximum load of the drying rack is limited. The corresponding control circuit board is also due to the large working current. high cost.

3. The diameter of the reel is small. Due to the elasticity of the wire rope itself, when the wire rope is not subjected to sufficient load, the problem of chaotic entanglement of the wire rope is prone to occur, resulting in unsmooth lifting.

4. The EMC electromagnetic radiation is large.

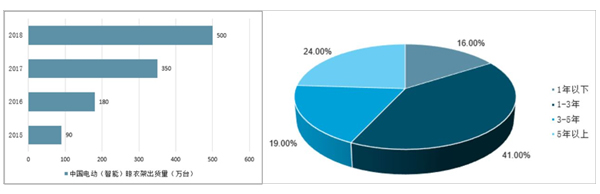

5. The service life of the motor is insufficient. According to the statistics, the service life is as follows:

To solve the problems of the motor on the existing market, Power Motor proposed new electric clothes drying rack solutions by optimizing gear design and motor design:

1. Reduced the volume, change the height of the whole machine is 10mm lower than the product on the market, which provides the possibility to reduce the thickness of the main box of the drying rack. The total reduction in weight 200g

2. Optimize the gear transmission system, improve the transmission efficiency, effectively reduce the working power of the motor, reduce the working current, and reduce the load of the electronic components on the circuit board.

3. The large winding wheel design reduces the height of the winding wheel and reduces the risk of entanglement.

4. Optimize the motor circuit to suppress the electromagnetic radiation of the motor.

5. Reduce the bending curvature of the wire rope, effectively extending the service life of the wire rope.

In the future, Power Motor will optimize the design and use brushless motors instead of brush motors to further increase the service life of the motors. With the rise and gradual popularity of smart homes, the use of brushless motors can achieve intelligent control.

Power Motor has nearly 20 years of experience in motor customization engineering, accumulated large motor sample database for reference, optional matching controller or encoder, quickly according to customer needs to custom a motor solution meet or exceed customer demand. More information on the electric clothes drying rack motor solution, Please contact our sales engineer.(Skype/Email:info.power@power-motor.com)

Share

Share