BLDC Motors: The Electric Drive in Modern Vehicles

Many of the advanced features in today's cars rely on a specific type of electric motor. BLDC, which stands for Brushless Direct Current, describes a motor that operates without the physical brushes found in traditional designs. This technology is fundamental to the evolution of vehicle systems, from basic comfort features to the very powertrain that moves the car. We will examine how a BLDC car motor functions and why its characteristics make it a superior choice in many automotive applications compared to conventional brushed and brushless dc motor options.

Electronic Control Replaces Mechanical Parts

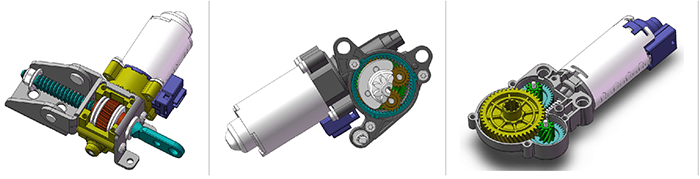

The primary distinction of a BLDC motor lies in its method of operation. Traditional brushed DC motors use carbon brushes and a mechanical commutator to deliver power to the rotating part of the motor. A BLDC car motor inverts this design. It places permanent magnets on the rotor and surrounds them with a stationary set of copper windings called the stator. An external electronic controller precisely energizes these stator windings in a specific sequence. This creates a rotating magnetic field that pulls the rotor around, eliminating the need for any physical contact to transfer electricity to the moving part. This core difference in how a brushed and brushless dc motor functions is the source of the BLDC's major benefits.

Key Advantages for Automotive Use

The brushless design delivers several performance characteristics that are highly valuable in vehicles. The absence of brushes means there is no arcing, less electrical noise, and no brush dust to compromise the motor's internals. This leads to a much longer service life and greater overall reliability. Furthermore, BLDC motors are highly efficient. Without the friction and voltage drop caused by brushes, more electrical energy is converted into mechanical motion. For a primary drive motor, this efficiency directly increases a vehicle's driving range. For auxiliary systems, it reduces the load on the alternator or battery, improving fuel economy. The robust nature of a BLDC car motor makes it well-suited for the demanding environment under the hood.

Diverse Roles from Comfort to Propulsion

The application of BLDC technology in the automotive sector is extensive. Its most prominent role is as the traction motor in electric and hybrid vehicles, where it provides the torque needed to drive the wheels. Beyond propulsion, these motors are integral to numerous other systems. They are the driving force behind electric power steering, offering responsive assist without a hydraulic pump. They operate the compressors in air conditioning units and drive the cooling fans for radiators and battery packs. The compact power and precise control of a BLDC car motor allow it to be adapted for these varied tasks, making it a versatile component in modern automotive engineering.

The integration of BLDC technology represents a significant step forward in automotive design. The durability, efficiency, and controllability of BLDC motors from Power Motor meet the high standards required for vehicle components. As electrification continues to advance, the presence of these advanced motors is expected to expand, with Power Motor supporting the development of more sophisticated and efficient transportation solutions.