What Does "Brushless" Mean in a Power Tool?

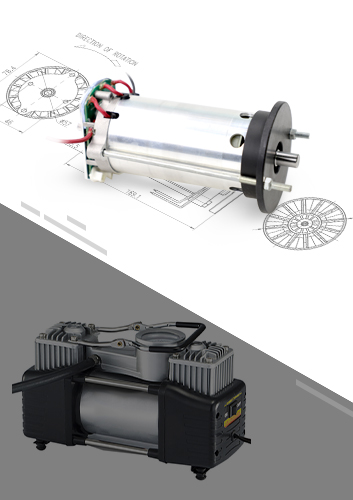

For professionals who rely on their equipment, the internal mechanics of a power tool directly influence its performance and reliability. A term that has moved from a premium feature to a common specification is "brushless." This description signifies a fundamental change in the core of the tool—the motor. At Power Motor, our work as a brushless motor manufacturer is centered on this advanced technology. It represents a shift from a traditional, friction-based system to an electronically managed one. Understanding what "brushless" means requires a look at the engineering principles that make it a different class of device.

The Core Principle: Eliminating a Physical Connection

The defining characteristic of a brushless motor is the removal of the physical components that create friction in traditional motors. In a conventional brushed motor, the system depends on carbon brushes that are spring-loaded to press against a spinning commutator. This physical contact transfers electrical current to create rotation but also generates significant friction, sparks, and heat. Over time, the brushes wear down and require replacement. As a brushless motor manufacturer, we design systems that operate without this sliding contact. The architecture is reversed; the permanent magnets are situated on the rotor, and the copper windings become part of the stationary stator. This fundamental redesign is what enables the subsequent advantages.

The Intelligent Director: Electronic Commutation

The operation of a brushless motor is managed by a sophisticated electronic controller. This unit acts as the brain of the system, performing a function known as electronic commutation. The controller uses sensors to constantly monitor the position of the rotor. It then delivers pulses of power to the stator's windings in a precise, timed sequence. This creates a rotating magnetic field that pulls the rotor around with optimal efficiency. Because the controller can sense resistance, it adjusts the power output in real-time. This provides consistent torque when driving a long screw and maintains speed when cutting through dense material, a capability that is central to our development as a brushless DC motor manufacturer.

The User Experience: Measurable Performance Gains

The internal efficiency of a brushless motor translates into several practical benefits for the end-user. The most direct impact is on battery runtime. Since no energy is wasted on overcoming the friction of brushes, or lost as heat and sparking, a greater proportion of the battery's charge is converted into useful work. This can lead to a marked increase in work completed per charge. Furthermore, the absence of consumable parts like brushes gives the motor a substantially longer operational lifespan, reducing maintenance needs and tool downtime. The precise control offered by the electronic brain also allows for smoother startup and more consistent power delivery under varying loads, which can improve control and the quality of the work.

The adoption of brushless technology marks a clear evolution in power tool design. It is a move from a electro-mechanical system prone to wear to a electronically governed one defined by efficiency and control. For our team at Power Motor, functioning as a dedicated brushless motor manufacturer and brushless DC motor manufacturer, the focus remains on refining this technology. We are committed to providing the durable, efficient, and intelligent motor systems that meet the demands of modern professional applications.