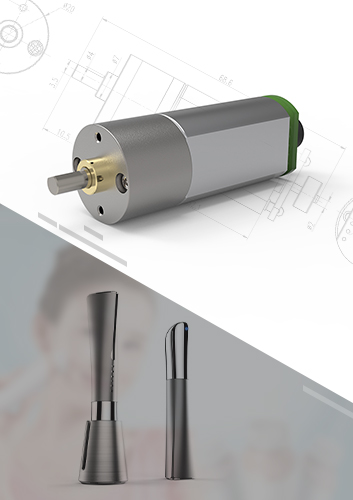

Gearbox Motors: Combining Force and Control

Many of the devices in our industrial and daily lives require two things: rotational force and the ability to control its speed. This is where a motor with gear box becomes an essential component. At Power Motor, we specialize in integrating these systems to create efficient and powerful solutions. Simply put, this combination is a single unit that merges an electric motor with a set of gears, and its job is to adjust the motor's output to the exact needs of an application. Let's break down how this common but vital piece of engineering works.

The Gear Reduction System's Essential Role

The primary role of the gearbox is to manage the relationship between speed and torque. An electric motor, by itself, often spins very fast but with relatively low force, or torque. For many applications, such as moving a heavy conveyor belt or powering a lift, you need more force and less speed. The gears inside the motor with gear box work as a reduction system. As they interlock, they trade the motor's high rotational speed for greater output torque. This process, known as gear reduction, allows a small, fast-spinning motor to generate the immense strength needed for demanding tasks without stalling or being damaged.

Where Brushless Motors Elevate the System

The type of motor used in this assembly significantly impacts its performance and longevity. This is where our work as a brushless motor manufacturer becomes critical. A brushless DC motor operates with electronic commutation, which eliminates the physical brushes found in traditional motors. When we build a unit as a brushless motor manufacturer, we are creating a core that is more efficient, generates less heat, and has a much longer operational life. Integrating a brushless motor into a gearbox assembly results in a system that is not only powerful and controllable but also remarkably reliable and quiet, making it ideal for continuous-use scenarios.

Practical Applications of an Integrated Drive

You will find a motor with gear box at work in a wide array of equipment. In the automotive industry, they power electric windows and adjustable seats, providing the necessary force for movement. In industrial automation, these units drive the precise movements of robotic arms and conveyor systems. They are also inside medical devices, aerospace actuators, and even sophisticated consumer products. The versatility of the gearbox motor comes from its ability to be customized; by changing the gear types and ratios, we at Power Motor can tailor the output characteristics to suit a specific force and speed requirement for virtually any application.

The integrated gearbox motor is a fundamental driver in modern machinery, providing a customized balance of speed and torque that a standalone motor cannot. By combining the rugged reliability of a gear train with the advanced efficiency of technologies from a dedicated brushless motor manufacturer, these systems deliver precise mechanical power exactly where and how it is needed. For engineers designing new systems, the selection of the right motor with gear box is a decisive step toward achieving optimal performance and durability.