A Methodical Approach to Electric Seat Repair

Electric seat adjustment issues can transform a comfortable drive into a source of frustration. These systems rely on a network of components, with a small motor at their heart. At Power Motor, our expertise in producing both brushed and brushless dc motor units for automotive applications gives us a unique view of the electric adjustable seat for car systems. Addressing a malfunction involves a logical process of elimination, starting with the most accessible components before considering the motor itself.

Verifying Power and Basic Connections

The first area to inspect is the electrical supply. A common culprit is a simple lack of power. Begin by checking the relevant fuse in the vehicle's fuse box; a blown fuse will prevent the seat from receiving any electricity. If the fuse is intact, the issue may lie with the seat's switch. Listen carefully for any faint sounds or feel for slight vibrations when pressing the switch. The absence of any noise or movement often points toward a faulty switch, a broken wire in the control circuit, or a problematic connection. These elements are easier and less costly to address than the motor assembly.

Inspecting the Mechanical Drive Components

If power is confirmed reaching the motor, the next step is to examine the mechanical parts. An electric adjustable seat for car system uses a series of gears, screws, and cables to translate the motor's rotation into physical movement. Over time, these components can wear out or become obstructed. Listen for a humming sound from the motor when the switch is activated; this noise typically indicates the motor is running but its torque is not being transferred. This could be due to stripped plastic gears, a jammed track from accumulated debris, or a broken drive cable. Visual inspection of the tracks and gears for obstructions is a useful diagnostic step.

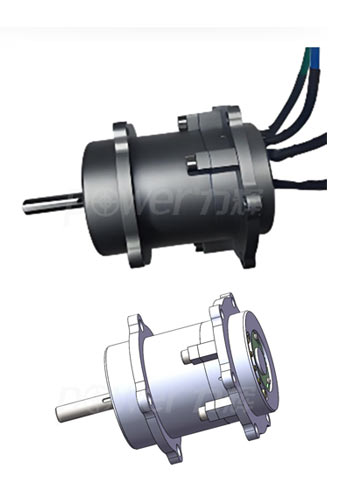

Assessing the Drive Motor Itself

The motor is the component we know best. Whether the system uses a brushed and brushless dc motor design, motors can eventually fail. A brushed DC motor, common in these applications, can experience worn-out carbon brushes or a damaged commutator, leading to intermittent operation or no operation at all. A brushless DC motor might have a failure in its internal electronics. If all other components—fuse, switch, wiring, and mechanical tracks—check out, the motor itself is likely the source of the problem. Testing the motor by applying power directly can confirm this, but this should be done with reference to the vehicle's service manual to avoid damage.

Resolving an electric adjustable seat for car problem is a systematic process. By checking electrical connections first, then mechanical linkages, and finally the motor, you can efficiently identify the root cause. For us at Power Motor, understanding the interplay between the brushed and brushless dc motor and the rest of the system is part of our daily work. This knowledge ensures that the components we produce meet the durability and performance demands of modern vehicle interiors.