A Practical Method for DC Motor Gear Removal

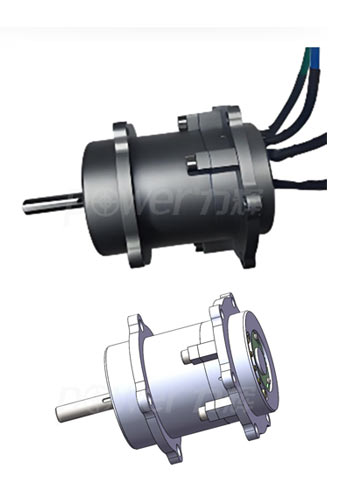

We often see inquiries at our facility about servicing and modifying motors. A recurring question we encounter is how to separate a gear from its motor shaft. This is a precise task that, when done correctly, can allow for repairs or custom configurations. As an established BLDC motor manufacturer and a DC gear motor manufacturers, we want to walk you through a reliable process for this delicate operation. Understanding the right approach helps prevent damage to the shaft and the gear itself, preserving the components for future use.

The Critical First Step: Understanding the Assembly

Before any tools are picked up, it is vital to identify how the gear is affixed. Most gears are secured using one of two methods: a press-fit or a setscrew. A press-fit gear is held in place by an extremely tight tolerance, literally pressed onto the shaft with significant force. A setscrew gear, however, uses a small screw threaded into the gear hub that tightens directly against the motor shaft. Look for a small hole on the side of the gear hub; if you see one, you have a setscrew assembly. This distinction dictates your entire removal strategy and is the most important part of the process. Misidentifying this can lead to immediate and costly damage.

Executing a Safe Removal Process

For a gear with a setscrew, begin by locating the screw and using the correct Allen key to loosen it completely. Once loose, the gear should slide off by hand, though a gentle pull from a gear puller may be necessary if it is stuck. For a press-fit gear, the procedure requires more care. A gear puller is the recommended tool. The jaws of the puller are positioned behind the gear, and the central screw is turned, applying even, backward pressure to draw the gear straight off the shaft. Applying heat with a heat gun to the gear hub can carefully expand the metal, making removal easier. It is crucial to avoid hammering or prying, as this can bend the motor shaft or shred the gear teeth.

Why Precision Matters in Component Handling

The primary risk during this entire process is damaging the motor shaft. Even a slight bend will cause significant vibration and lead to premature failure in the final application. Similarly, damaging the internal bore of the gear can compromise its grip on the shaft, leading to slippage. This level of care is something we integrate into every unit we build. Our experience as a dedicated BLDC motor manufacturer and one of the specialized DC gear motor manufacturers has shown us that the integrity of these components is non-negotiable for system longevity and performance.

Handling components from Power Motor with the correct technique ensures that your project proceeds smoothly and reliably. Whether you are replacing a worn gear or creating a custom solution, this methodical approach protects your investment in the motor and the gear. We designed our systems for durability, and proper maintenance extends their operational life significantly.