The Silent Synchrony: A Look at How BLDC Motors Function

Many of the advanced devices and industrial systems we interact with daily rely on a source of motion that is both efficient and exceptionally quiet. This quiet efficiency often comes from a Brushless DC, or BLDC, motor. At Power Motor, our work as a DC electric motor manufacturer centers on refining the principles behind these powerful components. Gaining a clear view of their operation reveals why the high-speed BLDC motor has become a preferred choice for precision engineering. Let's examine the step-by-step process that occurs inside these units.

The Fundamentals: A Set of Three Crucial Elements

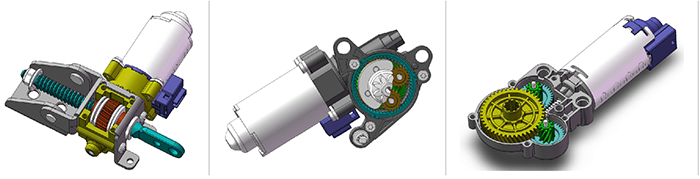

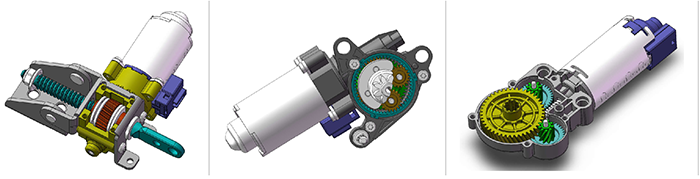

Every BLDC motor is built around three key elements. First, the stator, which is the stationary outer shell, contains windings that create magnetic fields when energized. Second, the rotor, the part that spins, is not a collection of wires but a permanent magnet with a fixed number of poles. Finally, surrounding the motor is an electronic controller, the brain that dictates the entire operation. This fundamental architecture is what we, as a DC electric motor manufacturer, engineer to exacting standards. The absence of physical brushes that wear out is what grants the BLDC its long service life and clean operation.

The Digital Orchestra: Precisely Sequencing Power

The true innovation of a high-speed BLDC motor lies in its method of commutation. Instead of using a physical brush and commutator bar to reverse current, it employs electronic switching. The controller constantly monitors the position of the rotor using Hall-effect sensors or similar methods. Using this real-time data, it intelligently energizes the stator windings in a specific sequence. Each activation creates a magnetic pole that either attracts or repels the permanent magnets on the rotor. This continuous, calculated push and pull is what causes the rotor to spin. The process is a rapid-fire digital conversation between the sensor and the controller, ensuring no energy is wasted on friction.

Driving Performance: The Outcomes of Electronic Control

This method of electronic commutation results in several distinct advantages. The most immediate is efficiency; without the constant friction and electrical arcing of brushes, more electrical power is converted into mechanical motion. This also allows a high-speed BLDC motor to achieve and maintain exceptional rotational velocities with stability. Furthermore, the electronic controller provides unparalleled command over the motor's torque and speed, enabling smooth startups and precise adjustments that are simply not possible with brushed designs. This level of control is a primary reason industries seek a sophisticated DC electric motor manufacturer for applications requiring accuracy and reliability.

The operation of a BLDC motor is a testament to the shift from electromechanical to electronic precision. By replacing physical brushes with a smart controller, we achieve a system defined by its efficiency, durability, and exceptional control. For our team at Power Motor, deepening the understanding of these principles is the foundation for developing the next generation of motion solutions.