Reliable Motion Solution Provider & Manufacturer

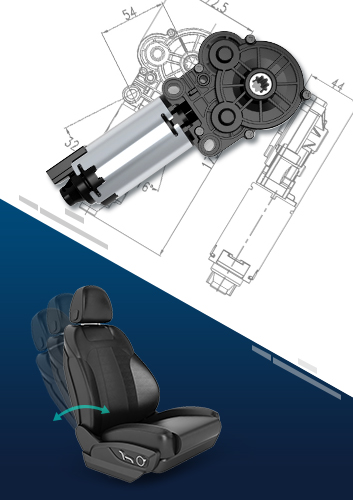

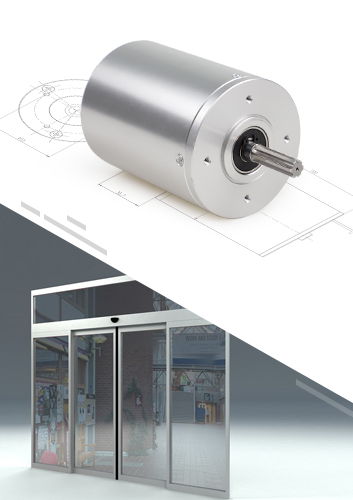

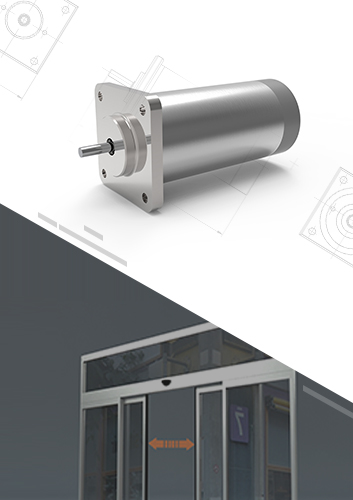

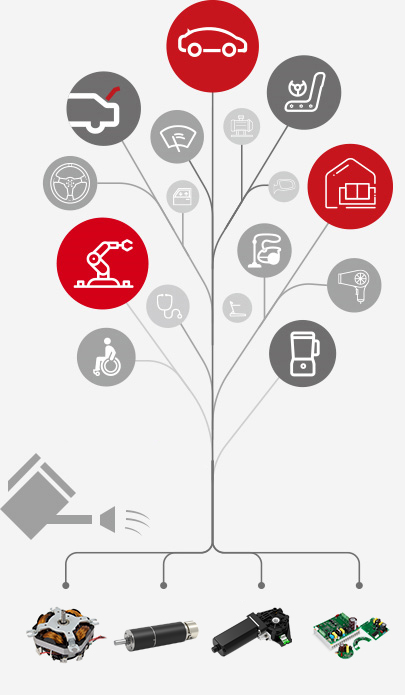

Shenzhen Power Motor Industrial Co., Ltd.(Power Motor) has been a reliable motion solution manufacturer since 2001. Our mature motor technology, application expertise and perfect customized platform make Power Motor the ideal partner for customing product development projects. Power Motor is committed to making our customers successful by providing product differentiation and supply chain excellence. For designers who demand performance leadership and assurance of supply, Power Motor is the reliable choice. We serve many industries including smart home and appliances, automotive, healthcare, smart agriculture, industrial automation and power tools.More+

20 years of motor design & innovative solution experience

40+ automatic and semi-automatic production lines, 3 million motors/month

Automation production line localization and innovation

Considering the rationality and convenience of the production process from the design stage

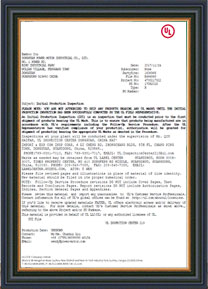

Adopting the international advanced quality management system, strict management of IQC, production and QA

Customer needs analysis team respond to customer quickly and professionally

Professional sale engineers provide one-stop customized services

Motor application database provides reference data to save development cost.

Our perfect and stable supply chain system, with obvious location advantages, saving logistics costs.

Automated production and very low defect rates have reduced costs.

On March 10, 2022, Power Motor unveils a new series of motor solutions for cordless hand blender. PT2730 series and PT555PM series provides a comprehensive motion solution for cordless hand blender or mixer. The highly integrated product as···

LEARN MOREWe use cookies and similar technologies on this website ("Cookies"). In order to allow their use to analyze website usage and to enhance functionality, please click on "Use all functions". To change the settings and select which specific Cookies we are allowed to use, or to obtain more detailed information, please click on "Settings".

Below, you can activate/deactivate the individual technologies that are used on this website.